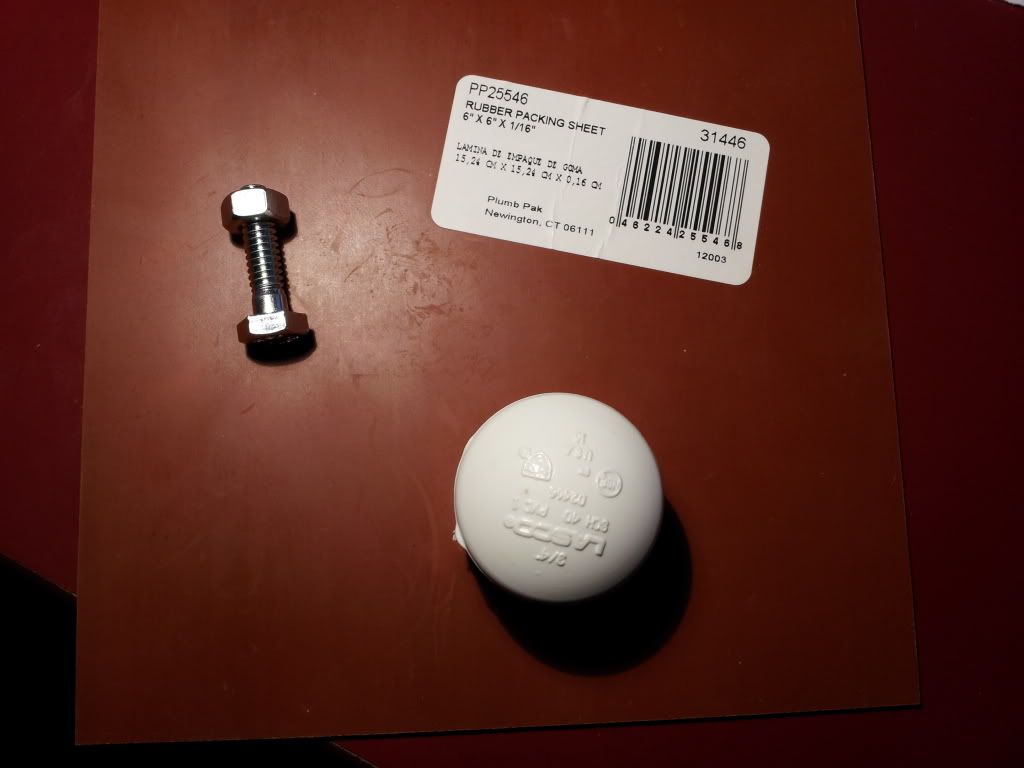

Its a 3/4" PVC cap (a bit bigger than 1" pipe), a screw and nut, and a "rubber packing sheet" I got at Lowes.

Anyone used this rubber before?

Thanks

lol silicon wont seal shit make sure you get the barrel square in the barrel and put epoxy around the bolt to stop air going thought there.Proxywars wrote:Yesir. Just stick with silicone and high pressures and you will have no leaks my friend.

Geese..... I got myself thinking on my gun how the piston was a tight fit. But with his it's not the same case so he doesn't need oils... My mistake...Gun Freak wrote:Proxywars... Shut up.

OP, you'll need a washer to hold down the rubber in the front, it will probably just slip off the nut. What chamber size is this for?

Sorry thinking of my gun when I posted that.. Piston got caught on a dent and oil helped it...Crna Legija wrote: lol silicon wont seal crap make sure you get the barrel square in the barrel and put epoxy around the bolt to stop air going thought there.

Also when you sand the cap to fit in the pipe, do it slowly and keep testing to see as soon as it fit stop the tighter the better so long it slides nicely.

Oiling would improve performance as it would allow the piston to move with less friction.Proxywars wrote:You wont need oils unless your piston is a little snug in the chamber. We all would like to see that puppy firing soon though.