I think the dead space may be too big.

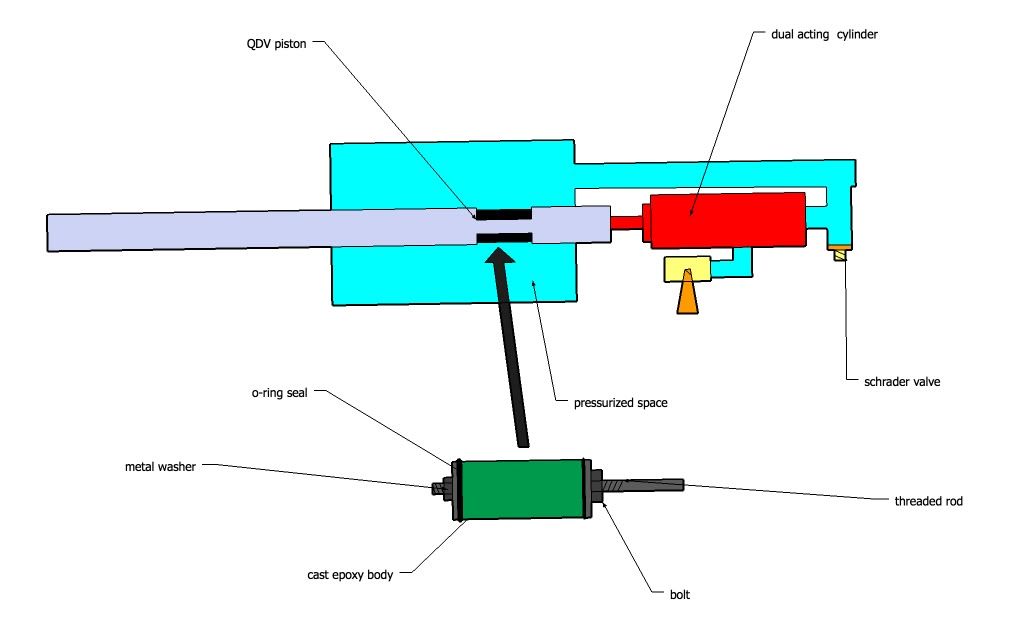

The picture:

Uploaded with ImageShack.us

The link:

http://yfrog.com/2gpneumaticqdvp

i hope to hear from you. If there are questions, ask me.

hectmarr wrote:You have to make many weapons, because this field is long and short life

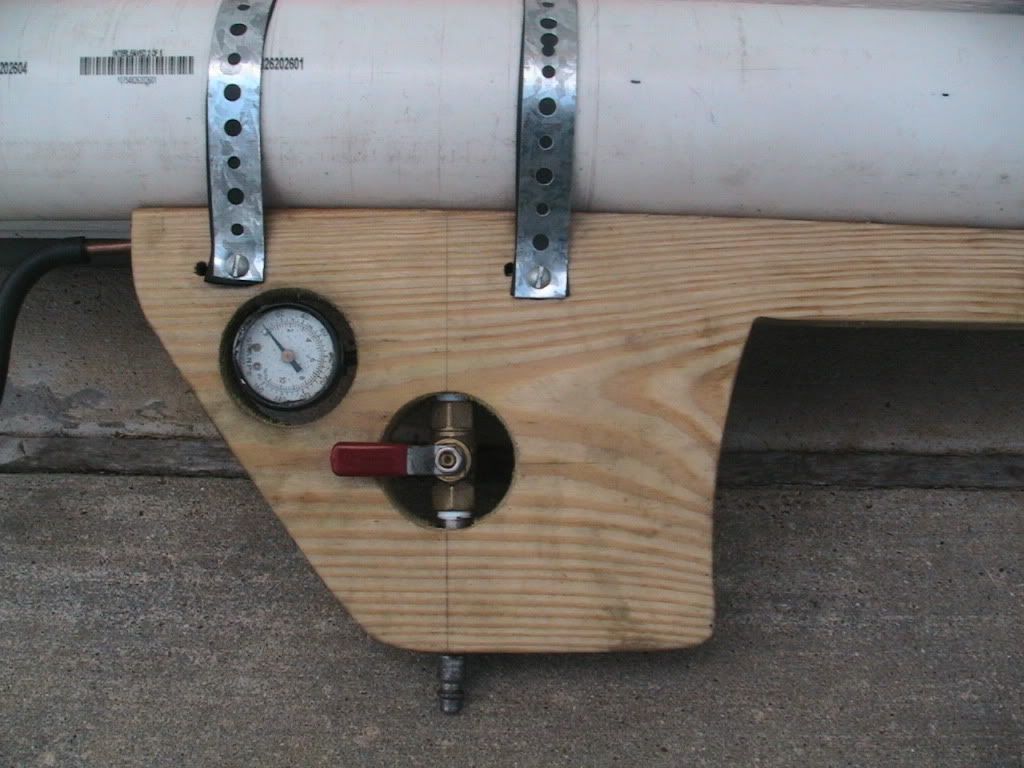

I think so. Sweet. Nice cannon. I hope the main piston is decoupled from the rod so the rod isn't getting a beating. Good luck with a bumper. It will need it. Try the inside of a dense foam football such as a Poof brand. The one I use in the ABS cannon sheds a little from wear, but is holding up well.Did I beat every body to an air pressure activated QDV?