GB Semi

-

clide

- Corporal 3

- Posts: 784

- Joined: Sun Mar 06, 2005 3:06 am

- Location: Oklahoma, USA

- Been thanked: 1 time

Yeah, it could be made in a tee, but if you want it to close at a higher pressure then the middle piston needs to be significantly larger than the other two. Which means your going to have to have something like a 2" tee for a 1" porting valve.

Opening speed is still quite fast because once it begins to open it has the same jump in force that a standard barrel sealing valve will experience. Using GGDT on the results I got from the sprinkler valve and the GB Semi indicates that that the GB Semi has more advantage than just the larger effective chamber volume. I know at least some of this is due to better valve flow because this is nearly an inline valve, but I think it is opening pretty darn quick.

Full auto is prevented just by being quick to release the trigger, The full auto on the tweaked gun isn't quite as fast as you see in the first video so it is easier to stop. I guess that technically makes it an auto that works works best firing semi-auto, but it was designed for semi-auto operation and the fact that it might work as an auto was just an afterthought.

Thanks again to all those who left comments.

Opening speed is still quite fast because once it begins to open it has the same jump in force that a standard barrel sealing valve will experience. Using GGDT on the results I got from the sprinkler valve and the GB Semi indicates that that the GB Semi has more advantage than just the larger effective chamber volume. I know at least some of this is due to better valve flow because this is nearly an inline valve, but I think it is opening pretty darn quick.

Full auto is prevented just by being quick to release the trigger, The full auto on the tweaked gun isn't quite as fast as you see in the first video so it is easier to stop. I guess that technically makes it an auto that works works best firing semi-auto, but it was designed for semi-auto operation and the fact that it might work as an auto was just an afterthought.

Thanks again to all those who left comments.

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

You have my vote.I hate the look, but I love the concept and function!

You have given us the first really new valve in a long time.

It combines three idea's I have had, but gave up on and made them work, all in one cannon!!

The design is actually pretty straight forward.

The sear could be improved to withstand more force, yet still function smootly and effortlessly.You could use that force to either operate at higher pressures, or make the valve open faster.

You have given us the first really new valve in a long time.

It combines three idea's I have had, but gave up on and made them work, all in one cannon!!

The design is actually pretty straight forward.

The sear could be improved to withstand more force, yet still function smootly and effortlessly.You could use that force to either operate at higher pressures, or make the valve open faster.

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

Double post ( can't edit for some reason)

Here's my idea ( used it in crossbows in a different way)

Here's my idea ( used it in crossbows in a different way)

- Attachments

-

- sear.JPG (22.65 KiB) Viewed 7610 times

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

so how did you tweak it, did you tweak it deliberately,

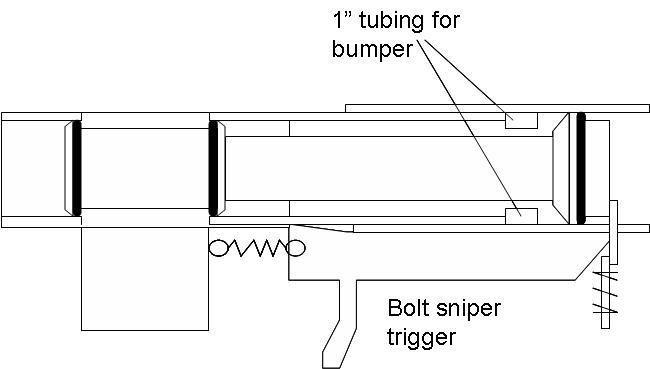

let me get this straight the the seal on the left, the single one that is behind the input is the has the second largest diameter, the middle is the largest, and the right barrel sealer is the smallest, this makes sense to me or else I see an equilibrium and can't imagine movement, am I right so far if not ignore the rest of this post

so full auto must not be as strong because the block isn't stopping it from building up that little extra pressure, to fix that add a delay mechanism something that adds some pop in the actuation, my recommendation is a roller delay, a small spring loaded roller with a screw/bolt behind the spring so you can adjust tention

let me get this straight the the seal on the left, the single one that is behind the input is the has the second largest diameter, the middle is the largest, and the right barrel sealer is the smallest, this makes sense to me or else I see an equilibrium and can't imagine movement, am I right so far if not ignore the rest of this post

so full auto must not be as strong because the block isn't stopping it from building up that little extra pressure, to fix that add a delay mechanism something that adds some pop in the actuation, my recommendation is a roller delay, a small spring loaded roller with a screw/bolt behind the spring so you can adjust tention

- paaiyan

- First Sergeant

- Posts: 2140

- Joined: Wed Dec 27, 2006 10:03 pm

- Location: Central Oklahoma

- Been thanked: 1 time

PCGuy disable edits in contest entry forums so no one could cheat by changing the spacs after the deadline.Brian the brain wrote:Double post ( can't edit for some reason)

Here's my idea ( used it in crossbows in a different way)

"Who ever said the pen was mightier than the sword, obviously, never encountered automatic weapons."

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-General Douglass MacArthur

Read my dog's blog - Life of Kilo

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

-

clide

- Corporal 3

- Posts: 784

- Joined: Sun Mar 06, 2005 3:06 am

- Location: Oklahoma, USA

- Been thanked: 1 time

Thanks Brian.

I think the sear I have now will work fine for my purposes. But I'll certainly keep that sear in mind because it will hold more force.

What don't you like about the look? I worked pretty hard to make it clean and compact. I know it needs a paint job, but beyond that what don't you like?

The main tweak was that I made the piston heavier. Since part of the return stroke is powered by the inertia of the piston, a heavier piston helps ensure that it is reseting fully each time and makes the piston stay in the closed position longer.

Full auto may be a little weaker, but I don't think it was by a huge amount. Once you start firing, the secondary chamber allows a more consistent flow from the compressor. The air line between the secondary and the main chamber is 1/2" and this allows for air to transfer from the secondary to the main chamber very quickly.

After firing I didn't notice any sound that would indicate that the gun pressure dropped significantly below the line pressure (like what is heard when the gun is first pressurized), but I'll see if I can get any hard data once I fix the bolt.

I think the sear I have now will work fine for my purposes. But I'll certainly keep that sear in mind because it will hold more force.

What don't you like about the look? I worked pretty hard to make it clean and compact. I know it needs a paint job, but beyond that what don't you like?

The main tweak was that I made the piston heavier. Since part of the return stroke is powered by the inertia of the piston, a heavier piston helps ensure that it is reseting fully each time and makes the piston stay in the closed position longer.

Full auto may be a little weaker, but I don't think it was by a huge amount. Once you start firing, the secondary chamber allows a more consistent flow from the compressor. The air line between the secondary and the main chamber is 1/2" and this allows for air to transfer from the secondary to the main chamber very quickly.

After firing I didn't notice any sound that would indicate that the gun pressure dropped significantly below the line pressure (like what is heard when the gun is first pressurized), but I'll see if I can get any hard data once I fix the bolt.

- rna_duelers

- Staff Sergeant 3

- Posts: 1739

- Joined: Mon Sep 26, 2005 7:07 am

- Location: G-land Australia

Thought I might say,this got my vote in the contest.And were is the new video link?

- ShowNoMercy

- Sergeant

- Posts: 1094

- Joined: Mon Mar 19, 2007 8:08 am

- Location: Jersey Bitches!

That is a very nice gun. I just finished replicating your slider design out of metal and now I will try to replicate this one.

Jesus saves, no need to pray

The gates of pearl have turned to gold

It seems you've lost your way

The gates of pearl have turned to gold

It seems you've lost your way

-

clide

- Corporal 3

- Posts: 784

- Joined: Sun Mar 06, 2005 3:06 am

- Location: Oklahoma, USA

- Been thanked: 1 time

rna, the newest video is embedded in the first post, it is the plywood one. The first video is linked to underneath the newer one. It looks like I've worked out the kinks in the loading mechanism today and will hopefully have a full auto video tomorrow.

Cool ShowNoMercy, can't wait to see it (you are going to post it right?)

Oh and I forgot to say in my last post that yes you are right about how it works iknowmy3tables. I've considered something like you describe, but I'll wait and see if I can figure out if or how much performance is decreased from full auto.

Cool ShowNoMercy, can't wait to see it (you are going to post it right?)

Oh and I forgot to say in my last post that yes you are right about how it works iknowmy3tables. I've considered something like you describe, but I'll wait and see if I can figure out if or how much performance is decreased from full auto.

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

Don't get me wrong, I think it's a very well built cannon, with attention to detail.

I don't mean to insult you.I like the fact you modify fittings to get a tighter design.I just don't like the still bulky bazooka kind of look.I'm into smaller guns myself.My latest creation is bulky and I find it ugly as well.The power should make up for it.Sometimes you'll have to make sacrifices to achieve a goal, in my case, I can't build a smaller gun with the same power, so I'm forced to go up to 2"steel..

I believe your gun was not built for it's shape, but to try out the concept, in wich you have succeeded.The overall look of the gun is therefore set.

The flush fittings and clean craftsmanship can't hide the bulky shape, although you have made it look it's best.

As we say in Holland, compared to the rest, "it sticks out with head and shoulders"..meaning your cannon is way more promising and innovative.

A lot of thought went into it.It gave me some idea's on how to adapt a valve I'm working on.( High pressure auto valve with high flow, but it will empty the chamber each shot, to each his own)

I don't mean to insult you.I like the fact you modify fittings to get a tighter design.I just don't like the still bulky bazooka kind of look.I'm into smaller guns myself.My latest creation is bulky and I find it ugly as well.The power should make up for it.Sometimes you'll have to make sacrifices to achieve a goal, in my case, I can't build a smaller gun with the same power, so I'm forced to go up to 2"steel..

I believe your gun was not built for it's shape, but to try out the concept, in wich you have succeeded.The overall look of the gun is therefore set.

The flush fittings and clean craftsmanship can't hide the bulky shape, although you have made it look it's best.

As we say in Holland, compared to the rest, "it sticks out with head and shoulders"..meaning your cannon is way more promising and innovative.

A lot of thought went into it.It gave me some idea's on how to adapt a valve I'm working on.( High pressure auto valve with high flow, but it will empty the chamber each shot, to each his own)

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

I just sketched a tee version of your valve, I find it easier to understand and make this way, and it has some resemblance of my inside out sleeve valve design only with a larger area in the back and a trigger release

I forgot to draw the air input

I forgot to draw the air input

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

WHAT THE CRAP THATS NOT THE PICTURE DANG THIS NO EDIT THING

I also forgot to say that it fits great into a nerf or paintball gun setup

I also forgot to say that it fits great into a nerf or paintball gun setup

-

clide

- Corporal 3

- Posts: 784

- Joined: Sun Mar 06, 2005 3:06 am

- Location: Oklahoma, USA

- Been thanked: 1 time

Oh yeah I know what you mean now Brian, I hate bulky guns too, but for what it is I am happy with how it worked out.

iknowmy3tables that design would work, but without the large middle piston it will have to be manually reset each time.

Apparently the loading mechanism isn't too fond of full auto because I am still having issues with it. Reviewing what videos I have indicates that I am up to a solid 3 RPS with semi-auto, and full auto is 9-10 RPS although that full auto figure will slow down when it is actually loading a projectile each time.

iknowmy3tables that design would work, but without the large middle piston it will have to be manually reset each time.

Apparently the loading mechanism isn't too fond of full auto because I am still having issues with it. Reviewing what videos I have indicates that I am up to a solid 3 RPS with semi-auto, and full auto is 9-10 RPS although that full auto figure will slow down when it is actually loading a projectile each time.

- Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

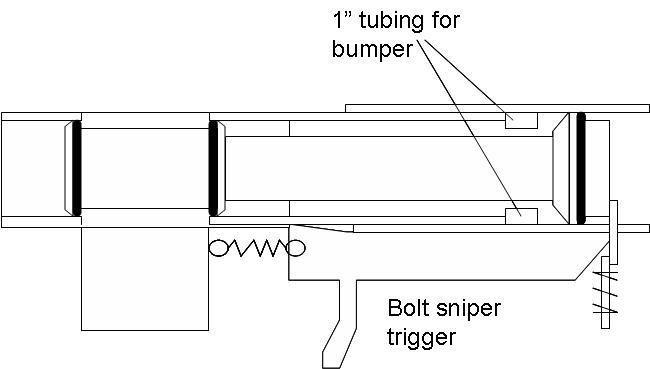

If you want full auto you will need to make a few changes.

This design ( see pic) has the larger surface area on the barrel side.

I

Pro's- valve snaps open once it reached critical pressure ( firing controlled by inlet valve)

Because of pressure drop in reservoir, while the "pilot"or, the pressure trapped behind the piston pushes it open like a regular piston valve.

Con's- No semi, most likely need more tuning to stop the entire reservoir from dumping( depends on spring)

Oh I forgot, the middle piston should have NO O-rings, just a snug fit, with "some" room for air to leak past it.

It might be nessesary to bleed the "pilot"at the point where the valve is at full opening, to get better performance.Could be achieved by a port in the back end of the piston assembly.

This design ( see pic) has the larger surface area on the barrel side.

I

Pro's- valve snaps open once it reached critical pressure ( firing controlled by inlet valve)

Because of pressure drop in reservoir, while the "pilot"or, the pressure trapped behind the piston pushes it open like a regular piston valve.

Con's- No semi, most likely need more tuning to stop the entire reservoir from dumping( depends on spring)

Oh I forgot, the middle piston should have NO O-rings, just a snug fit, with "some" room for air to leak past it.

It might be nessesary to bleed the "pilot"at the point where the valve is at full opening, to get better performance.Could be achieved by a port in the back end of the piston assembly.

- Attachments

-

- Meet the Full auto Brainvalve...

- Clidevalve auto.JPG (13.91 KiB) Viewed 7514 times

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!