Exhaust Valves.

I know the conventional easy way to exhaust your chamber using a fan is just unscrewing the cap from the chamber. I know that you can mod the cap and fit it with a valve to eliminate having to always unscrew the end cap. I have seen pictures online but have no idea how you mount that valve on the cap. Any hints.? All your input is extremely appreciated!!! Thank You.

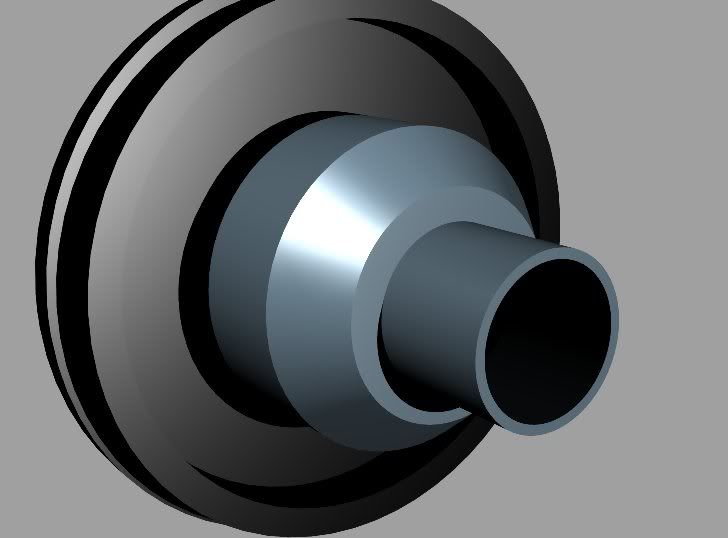

It actually should be setup as an intake for fresh air, with exhaust toward the barrel side of the chamber. Here's a picture of mine using a PVC ball valve like FordGTman mentioned:

Just open the valve for a few seconds between shots with the fan running. Be sure to close the valve to shoot!!

Just open the valve for a few seconds between shots with the fan running. Be sure to close the valve to shoot!!

How do you clean your chamber if that valve is permanent? Don't you want a cap that screws off in case you need to replace your chamber fan? Also that is about the size of Chamber that I am building. Is that a 1/2 diameter metering pipe?? Please tell me I'm right??

The whole rear screws out of the clean-out, here like this.hansom72 wrote:How do you clean your chamber if that valve is permanent? Don't you want a cap that screws off in case you need to replace your chamber fan? Also that is about the size of Chamber that I am building. Is that a 1/2 diameter metering pipe?? Please tell me I'm right??

The rear is built up with a series of reducer bushings to get down to the 1" threaded PVC valve. Take a trip down to Home Depot and figure this out for youself.

That chamber is about 225 cu in and the metering pipe is 3/8" galvanized. The actual measurement in the meter pipe however is exactly 1/2" diameter, the number you should use in volume calculations. Remember volume calc of a cylinder is radius * radius * pi * length. I have to pump this meter with about 72 psi propane to get my ideal propane volume.

Once you get your meter built, fill it with water and do an exact measurement of the water that's poured out of it. You can measure your chamber volume the same way.

If at all possible, could you post a picture of your valve setup. Obviously you have a fitting that screws into the back like a cap would, but I have been looking at a few different hardware stores, (menards, Farm and Fleet, Ace hardware...) and i still can't find a 4'' end piece with threads that will reduce down to a valve. Pictures are worth a million words. I would greatly appreciate it. By the way thank you Starman for taking the time to post pictures and share your info with me.

OK this is the last one....

It's a 4" socket to 4" Male threaded adapter, 4"spig to 2" socket reducer bushing, 2" spig to 1" female threaded reducer bushing, 1" steel close nipple then screwed into the PVC valve.

I must tell you that you're going to have to learn how to figure this stuff out on your own....just by looking at it and knowing in your heart what you're doing. I suggest spending an afternoon or 2 roaming the plumbing aisles of Home Depot becoming acquainted with how plumbing parts fit together and plumbing terminology. This particular assembly could be configured several different ways.

It's a 4" socket to 4" Male threaded adapter, 4"spig to 2" socket reducer bushing, 2" spig to 1" female threaded reducer bushing, 1" steel close nipple then screwed into the PVC valve.

I must tell you that you're going to have to learn how to figure this stuff out on your own....just by looking at it and knowing in your heart what you're doing. I suggest spending an afternoon or 2 roaming the plumbing aisles of Home Depot becoming acquainted with how plumbing parts fit together and plumbing terminology. This particular assembly could be configured several different ways.

Starman thank you very much for the pic. Tonight I spent two hours searching the plumbing isles at Farm and Fleet and Menards..., i found that 4'' male thread adapter and configured something llike you have in your pic and was about to buy it, except that i have had problems with the large threads sealing on a couple other cannons i have built. Do you ever have any problems with leaks associated with using that style vent cap? Can you use thread paste?

Use a small 3 sided file to clean up your threads on that 4" adapter. The plastic molds don't always meet exactly evenly on those and leave ridges across your threads making it harder to screw in. You can use teflon tape or thread paste on the threads and that will make it much easier to thread as well as do a reasonable job of sealing, at least enough for a combustion cannon.hansom72 wrote:Starman thank you very much for the pic. Tonight I spent two hours searching the plumbing isles at Farm and Fleet and Menards..., i found that 4'' male thread adapter and configured something llike you have in your pic and was about to buy it, except that i have had problems with the large threads sealing on a couple other cannons i have built. Do you ever have any problems with leaks associated with using that style vent cap? Can you use thread paste?

Also, get yourself a rubber oil filter "wrench" to screw those things on and off with.

-

cannon freak

- Specialist 2

- Posts: 272

- Joined: Fri May 12, 2006 8:37 pm

- Location: New Brunswick, Canada

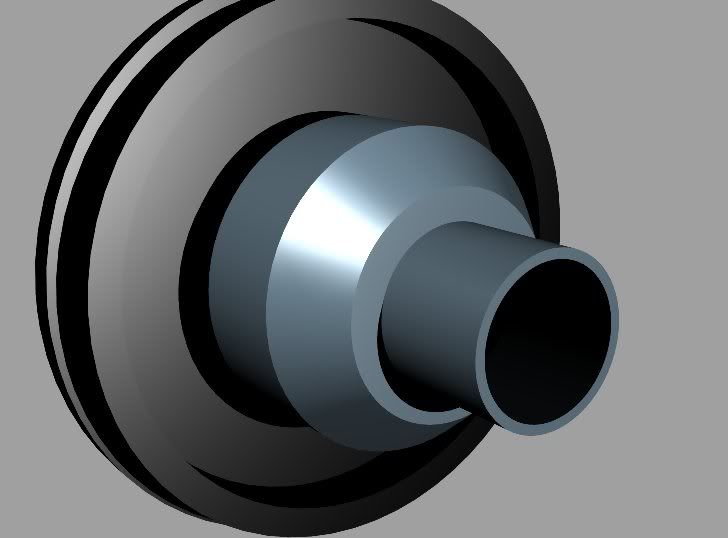

I simply use a 1" one way valve (all plastic $3) I found at the local hardware store end embedded that in my clean out end cap. Then attached a piece of garden hose to the one way valve and to a small matres inflator, works great, simply put your ammo in, inject the propane, and you don't even have to turn off the fan, just fire and the valve closes, then when the pressure drops the force of air will open the valve and start venting the gun out of the barrel. I use a breach loading system so the gases don't have to travel very far to be vented.

Here's a 3D model of the one way valve I'm talking about, I made last night while working on my Gatling Gun 3D model.

This is looking at it from the inside out, all that protrudes from the end cap are some threads.

Cannon Freak

Here's a 3D model of the one way valve I'm talking about, I made last night while working on my Gatling Gun 3D model.

This is looking at it from the inside out, all that protrudes from the end cap are some threads.

Cannon Freak