Harness the power of precision mixtures of pressurized flammable vapor. Safety first! These are advanced potato guns - not for the beginner.

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Mon Dec 13, 2010 9:34 pm

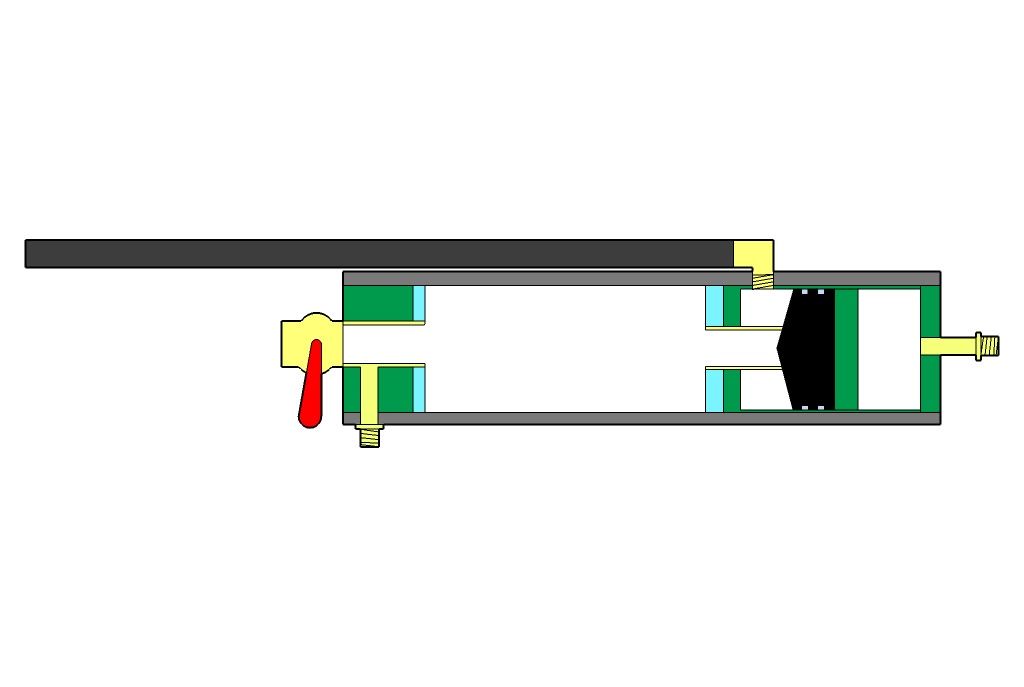

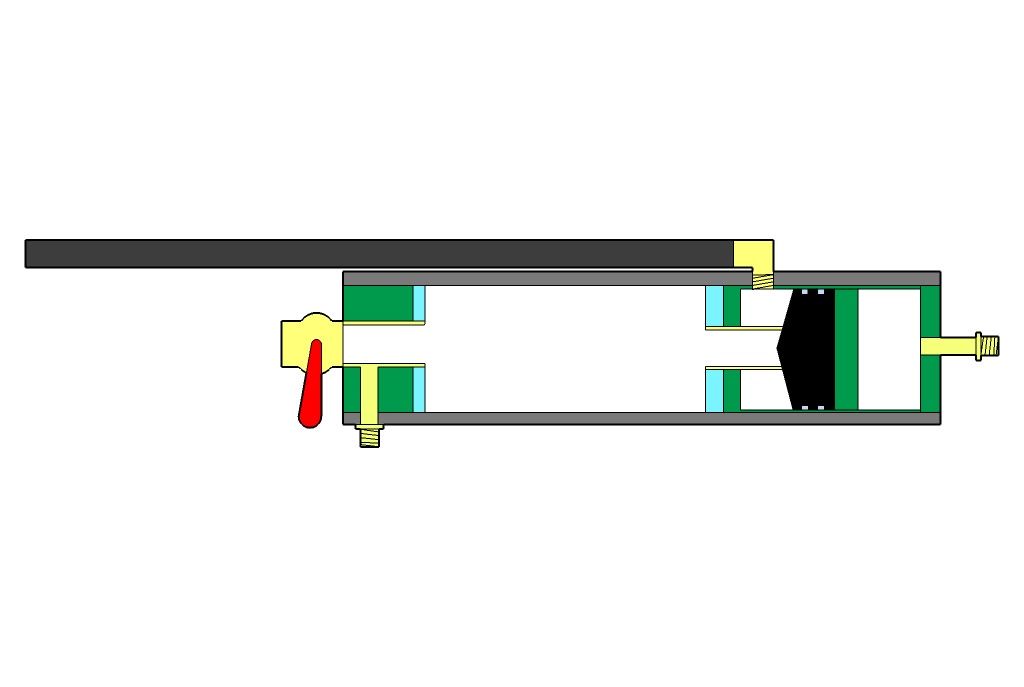

I finally got some decent epoxy, so I've been designing some pretty cool small projects to use it with. while I was designing away, I though of an extremely easy way to build a small piston hybrid. The only "special part" is the 60cc syringe I got from my biology class. The actual syringe head is used as the air tight pop-off piston. In the spirit of simplicity, I think I can get away with a simple pop-off piston without a proper pilot valve such as a spool valve or a pop-off valve.

I hope all the parts are clear, the whole thing is encased in a 1" copper tube

I love lamp

-

clemsonguy1125

- Sergeant 5

- Posts: 1485

- Joined: Tue Jul 21, 2009 4:00 pm

- Location: East Coast

Mon Dec 13, 2010 10:12 pm

Looks like it should work. An it could go full auto(with air). Looks a lot like jsrs rattlesnake valves. And they worked great.

Last edited by

clemsonguy1125 on Tue Dec 14, 2010 5:46 pm, edited 1 time in total.

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Mon Dec 13, 2010 10:34 pm

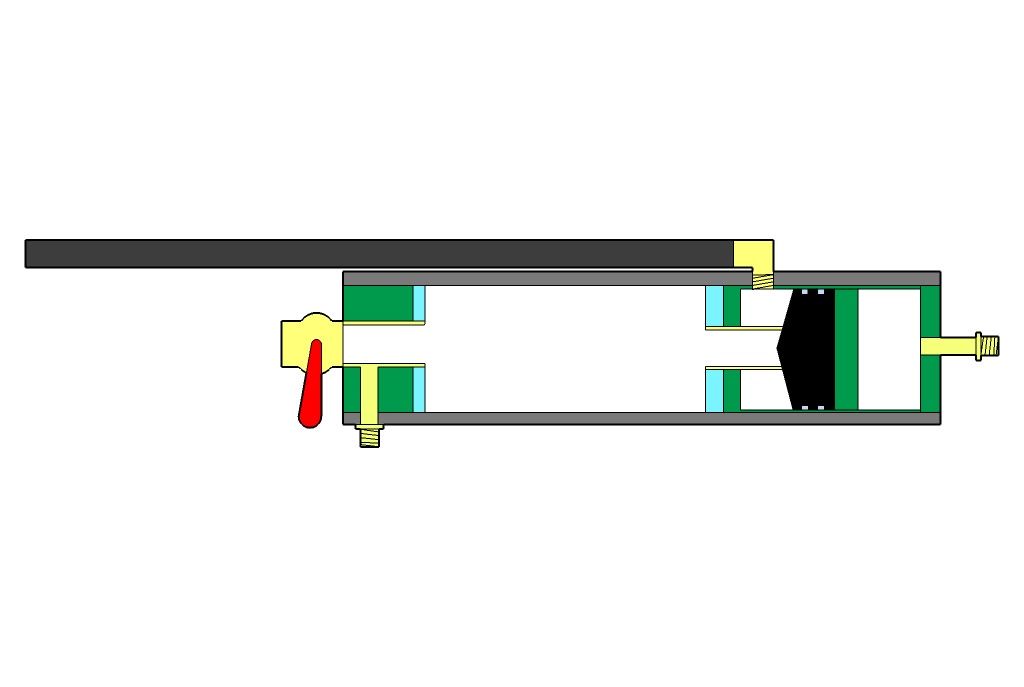

A little edit to the design, the back's gonna be serviceable so I can add a pop-off if needed

I love lamp

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Mon Dec 13, 2010 10:45 pm

interchangeable, but probably 3/8" porting, so a BB barrel would probably choke flow. I have to build the thing before I get ahead of myself and start changing things

I love lamp

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Dec 13, 2010 11:33 pm

Looks good, however 3 crucial points:

- the syringe body will

not survive a hybrid mix, it needs to be sleeved in a stronger material

- the piston seat needs a larger wall thickness so as not to cut into the rubber seal over time

- yay epoxy!

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Mon Dec 13, 2010 11:37 pm

-The syringe is sleeved in 1" copper with ¡EPOXY! sealing the gap.

-The piston seat will be a 3/8" nipple, Its not as thin as portrayed in the diagram.

-indeed...

I love lamp

-

Moonbogg

- Staff Sergeant 3

- Posts: 1735

- Joined: Mon Oct 13, 2008 10:20 pm

- Location: SoCal

- Has thanked: 164 times

- Been thanked: 101 times

Tue Dec 14, 2010 1:30 am

Right, well good thinking then! If you can make something that performs well at a low cost, then thats the elusive magic trick that seems to be within your grasp.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Tue Dec 14, 2010 1:40 am

Moonbogg wrote:If you can make something that performs well at a low cost, then thats the elusive magic trick that seems to be within your grasp.

It's not much more complex than my mini hybrids, I'm confident it can be made to work well with relative ease. Might be tempted to try something similar actually, burst disks are a bit of a pain!

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Tue Dec 14, 2010 8:43 am

I'll pour the epoxy later tonight, I just hope I still have that 1" copper tubing. So do y'all think I need a pop-off or spool valve behind the piston? And JSR, do you have any of your old HPA pop-off projects left? They could easily be converted to a low mix version

I love lamp

-

ramses

- Staff Sergeant 2

- Posts: 1679

- Joined: Thu May 29, 2008 6:50 pm

Tue Dec 14, 2010 10:01 am

You shouldn't. There will be a bunch more surface area exposed once it does pop. If the barrel chokes flow, pressure will build quite a lot in front of the piston. If the port of the piston valve chokes the flow (rather than something downstream of it) you may have issues, or just poor performance.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

-

Fnord

- First Sergeant 2

- Posts: 2239

- Joined: Tue Feb 13, 2007 9:20 pm

- Location: Pripyat

- Been thanked: 1 time

-

Contact:

Tue Dec 14, 2010 12:37 pm

The rear cast epoxy parts need to be thicker than the diagram suggests.

Also I don't think you need to have the seat protruding so far into the valve. You can cut a little dead space and overall length here.

-

Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

Tue Dec 14, 2010 2:13 pm

The distance the seat goes into the syring is to make sure the street elbow doesn't get in the way of the piston

@ JSR-

That is a much better setup, but I doubt I have that much skillz when it comes to complicated epoxy casting

I love lamp