ETAv2.1 High Velocity Launcher

Posted: Wed Sep 01, 2010 11:03 pm

Here we are at the end of the summer, and like always, I haven't got quite as much done as I'd hoped to. The new ETG design was supposed to be nearly impossible to destroy in normal operation with any energy level I could subject it to. Were it not for two simple flaws, that would probably be the case.

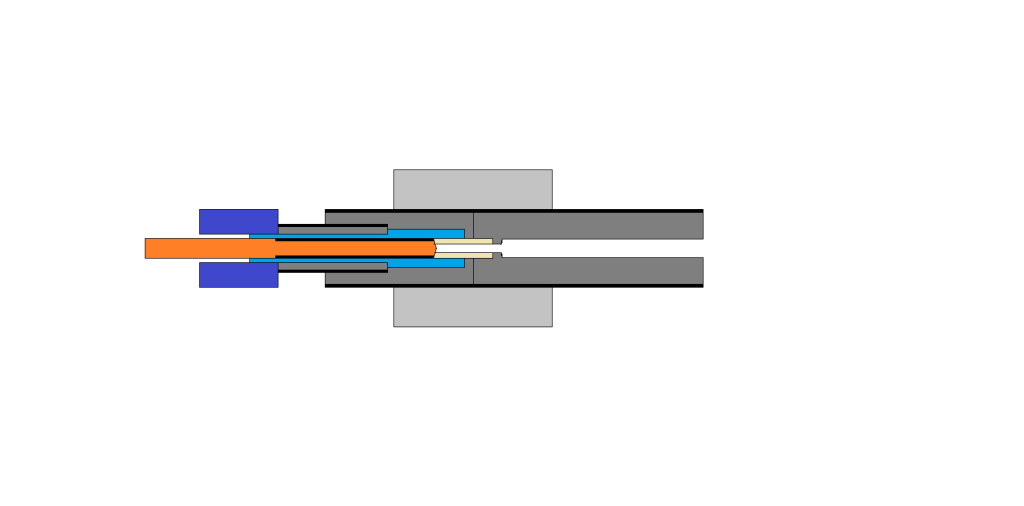

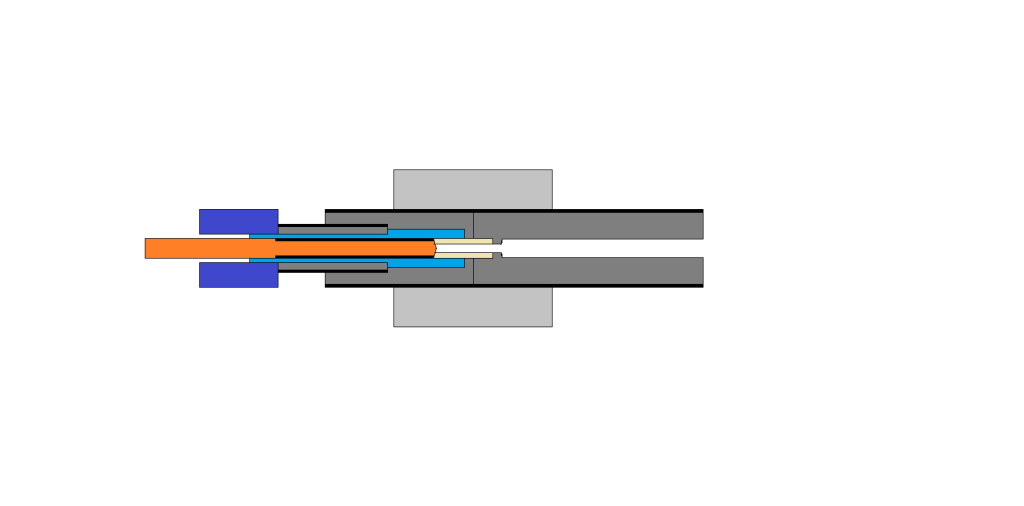

Firstly, a diagram:

Dark gray parts are 1"-8 steel threaded rod (except the thinner one, which is part of a 5/8"-11 grade 5 bolt). The one at the far right is the chamber, the one on the left is the insulator casing. Light gray is 2", annealed 8620 round stock with 1"-8 internal threads. Light blue is the internal insulator, tan is the capillary tube and dark blue is the external insulator (destroyed in a 5kJ surface arc and replaced with petroleum jelly). Not shown in the picture is the barrel, a rather complicated (but very solid) assembly consisting of five separate machined parts which isn't important to this discussion.

Specifications:

Chamber volume: variable. Effective volumes between 0.3 and 0.6mL have been used.

Bore: 6.2mm

Barrel length: 200mm

Firing energy: tested up to 5kJ

Working fluid: water

Efficiency: 10-20%, based on very limited testing

Firing voltage: up to 14kV (for 5kJ) Don't try this at home kids

Muzzle velocity: IT'S OVER NINE THOUSAND! (ft/s)*

Now, as the title suggests (not the current title, but the original one...), the pictures.

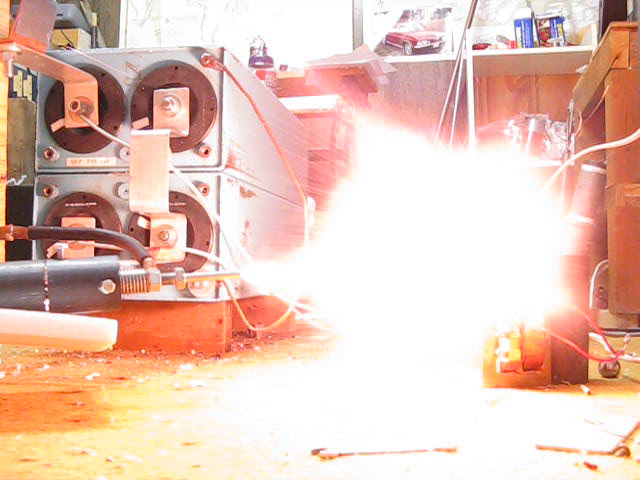

The launcher:

Muzzle flashes like this one are rare, but highly impressive.

Performance against a plasticine block with an airsoft round, at 2.5kJ input. Round in crater is for size comparison.

Performance against 1/8" aluminum plate with an airsoft round, at 3kJ.

Very nearly made it through. The crater is rippled, hinting of melting, and its diameter at the surface is uniformly 8mm (from a 6mm projectile).

Steel ball bearings go through 1/4" aluminum easily and leave 5mm deep holes in 3/8" plate (with back bulged out), even though the ETG fails violently when firing them, wasting much energy in the process. This occurs somewhere under 3kJ, so increasing energy past that does very little for performance.

Due to an issue with video conversion software, the acoustics of the indoor testing area, and my inability to coax a muzzle flash out of it while the FC150 is recording, videos are neither forthcoming nor interesting.

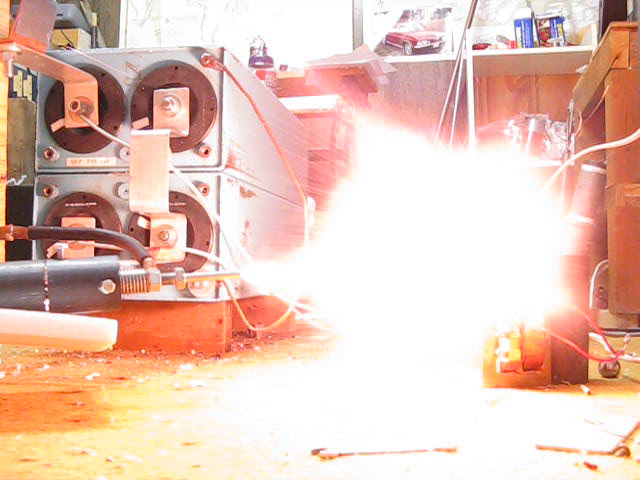

The ETG is part of an ongoing attempt on my part to produce hypervelocity impacts, and I'm well on my way to success. Muzzle velocity on the final shot with an airsoft round was between 2200m/s and 3100m/s (corresponding to 10-20% efficiency), and I noticed an effect which, to the best of my knowledge, no member of our community has ever created, much less captured on video: an impact flash. Muzzle is on the left, with the accompanying small muzzle flash. Target is aluminum plate on the right. Apologies for part of the flash being off-frame.

To me, that single frame is the most important result of the year. It is a perfect finish to my summer, visible indication that my goal is finally within reach. How impressed you are by it depends greatly on your own preferences, but I will say that Spudfiles has never seen the like of this launcher before. In energy density<sup>+</sup> and sheer muzzle speed, nothing here approaches it, not even HyGaC20.

Here's why it will never fire again.

Due to an immensely stupid design flaw on my part, the internal insulator is prone to firing out the back when the chamber pressure goes too high. It separates at the point where its diameter reduces, and the 1/2" of threads between that and the capillary tube are ripped out, allowing the newly freed fragment to escape, thus wasting huge amounts of gas and spraying the external insulator everywhere. Correcting this is simple, and will be done immediately at the start of next summer.

Also of concern is the tolerance of the hole that houses the internal insulator: as its bottom needs to be flat, an endmill is required to cut the last few millimetres. Because endmills do not self-centre, my 1/2" endmill expanded the hole to 0.52", creating enough extra volume to allow expansion, cracking, and general destruction of the insulator.

Next summer, there will be MUCH more. In the mean time, I appreciate any relevant comments, questions, and discussions. There are a few more pictures in my Photobucket gallery for your viewing pleasure, and more might appear over time.

*maybe

<sup>+</sup>Here defined as muzzle energy divided by total internal volume of the launcher

Firstly, a diagram:

Dark gray parts are 1"-8 steel threaded rod (except the thinner one, which is part of a 5/8"-11 grade 5 bolt). The one at the far right is the chamber, the one on the left is the insulator casing. Light gray is 2", annealed 8620 round stock with 1"-8 internal threads. Light blue is the internal insulator, tan is the capillary tube and dark blue is the external insulator (destroyed in a 5kJ surface arc and replaced with petroleum jelly). Not shown in the picture is the barrel, a rather complicated (but very solid) assembly consisting of five separate machined parts which isn't important to this discussion.

Specifications:

Chamber volume: variable. Effective volumes between 0.3 and 0.6mL have been used.

Bore: 6.2mm

Barrel length: 200mm

Firing energy: tested up to 5kJ

Working fluid: water

Efficiency: 10-20%, based on very limited testing

Firing voltage: up to 14kV (for 5kJ) Don't try this at home kids

Muzzle velocity: IT'S OVER NINE THOUSAND! (ft/s)*

Now, as the title suggests (not the current title, but the original one...), the pictures.

The launcher:

Muzzle flashes like this one are rare, but highly impressive.

Performance against a plasticine block with an airsoft round, at 2.5kJ input. Round in crater is for size comparison.

Performance against 1/8" aluminum plate with an airsoft round, at 3kJ.

Very nearly made it through. The crater is rippled, hinting of melting, and its diameter at the surface is uniformly 8mm (from a 6mm projectile).

Steel ball bearings go through 1/4" aluminum easily and leave 5mm deep holes in 3/8" plate (with back bulged out), even though the ETG fails violently when firing them, wasting much energy in the process. This occurs somewhere under 3kJ, so increasing energy past that does very little for performance.

Due to an issue with video conversion software, the acoustics of the indoor testing area, and my inability to coax a muzzle flash out of it while the FC150 is recording, videos are neither forthcoming nor interesting.

The ETG is part of an ongoing attempt on my part to produce hypervelocity impacts, and I'm well on my way to success. Muzzle velocity on the final shot with an airsoft round was between 2200m/s and 3100m/s (corresponding to 10-20% efficiency), and I noticed an effect which, to the best of my knowledge, no member of our community has ever created, much less captured on video: an impact flash. Muzzle is on the left, with the accompanying small muzzle flash. Target is aluminum plate on the right. Apologies for part of the flash being off-frame.

To me, that single frame is the most important result of the year. It is a perfect finish to my summer, visible indication that my goal is finally within reach. How impressed you are by it depends greatly on your own preferences, but I will say that Spudfiles has never seen the like of this launcher before. In energy density<sup>+</sup> and sheer muzzle speed, nothing here approaches it, not even HyGaC20.

Here's why it will never fire again.

Due to an immensely stupid design flaw on my part, the internal insulator is prone to firing out the back when the chamber pressure goes too high. It separates at the point where its diameter reduces, and the 1/2" of threads between that and the capillary tube are ripped out, allowing the newly freed fragment to escape, thus wasting huge amounts of gas and spraying the external insulator everywhere. Correcting this is simple, and will be done immediately at the start of next summer.

Also of concern is the tolerance of the hole that houses the internal insulator: as its bottom needs to be flat, an endmill is required to cut the last few millimetres. Because endmills do not self-centre, my 1/2" endmill expanded the hole to 0.52", creating enough extra volume to allow expansion, cracking, and general destruction of the insulator.

Next summer, there will be MUCH more. In the mean time, I appreciate any relevant comments, questions, and discussions. There are a few more pictures in my Photobucket gallery for your viewing pleasure, and more might appear over time.

*maybe

<sup>+</sup>Here defined as muzzle energy divided by total internal volume of the launcher