airsoft (madbull) grenade

this is for those airsofters that don't want to pay $90 for the madbull grenades. and for those that like to challenge themselves (as is all the topics i post from now on).

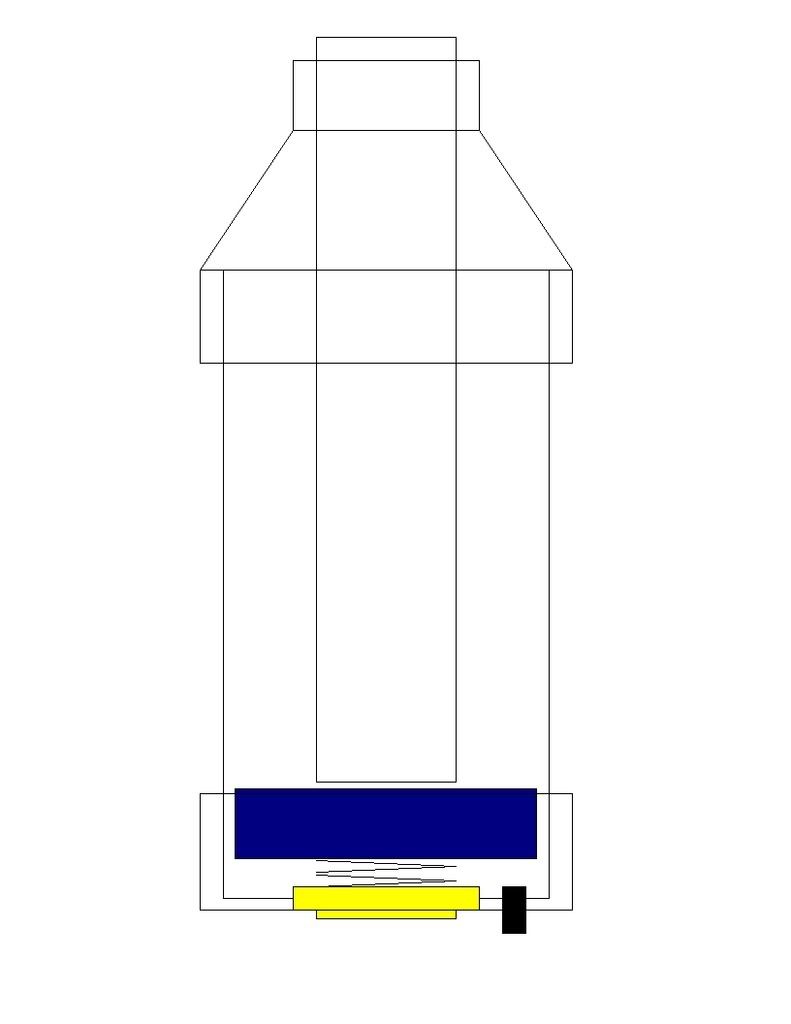

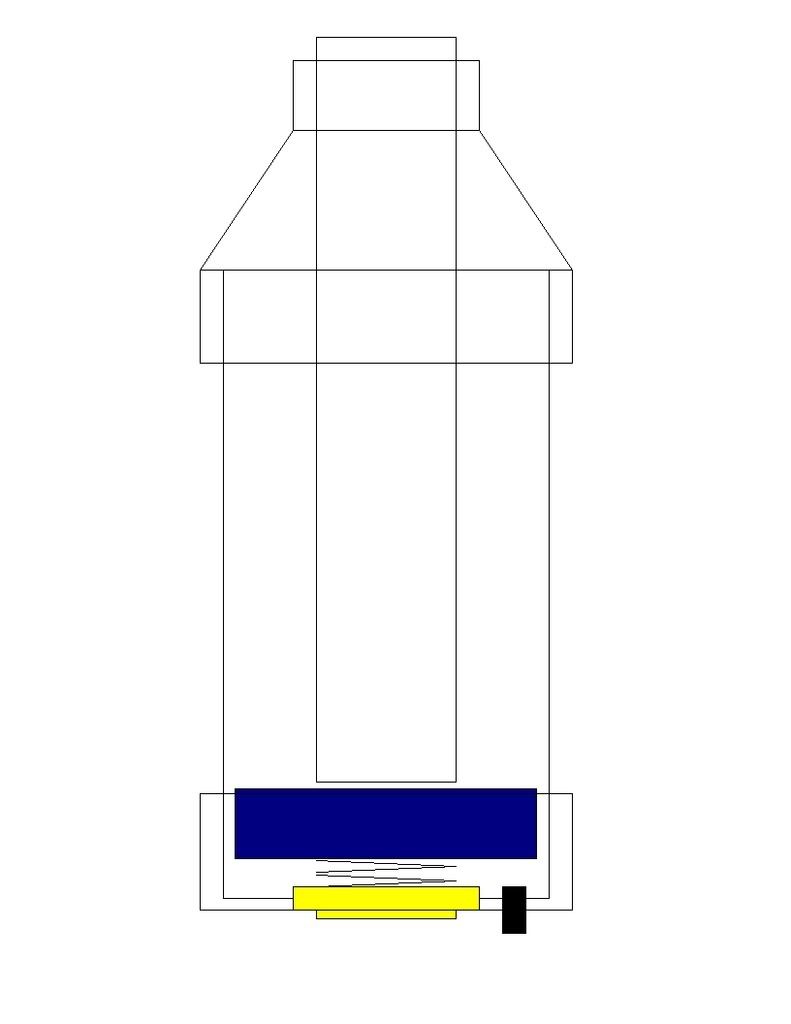

when i first saw this i kinda thought "that's it?". it's super simple. the valve is actually more of a release. this is a diagram that i found, reworked and color coded for easy viewing.

the first one is a model designed to fire a crap load of bbs at once. the second is my favorite cuz u can stuff anything in the barrel and it WILL fly out at about 500 fps (depending on diameter).

the yellow r the ball bearings which i feel r the heart of the whole assembly. kinda like a bolt in a door. when they r released into a clevis the the fun begins.

the orange is the plug. it blocks the gas. this must be sealed perfectly at all time. a good o-ring usually does it.

the green is the mechanism that keep the ball bearings locked. when it is pressed it releases the plug by freeing the ball bearings from a small wedge on the inner body. the wedge bares the load of the gas pressure against the plug.

the dark blue is the spring that keeps everything in check and make it easy to reset which is done by pushing the button release all the way in to set the plug then letting the button go to set the ball bearings.

the second design works kinda like a coaxial. a disk (blue) and the plug come together to make what i call a piston. the whole valve assembly work as a "mechanical pilot".

<a href="http://s90.photobucket.com/albums/k273/ ... img003.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... img003.jpg" border="0" alt="Photobucket"></a>

<a href="http://s90.photobucket.com/albums/k273/ ... img002.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... img002.jpg" border="0" alt="Photobucket"></a>

sorry if the pics r too big.

the valve can be easily recreated with a dremal, a dowel, ball bearings, and a few tubes that fit loosely but very close into each other.

when i first saw this i kinda thought "that's it?". it's super simple. the valve is actually more of a release. this is a diagram that i found, reworked and color coded for easy viewing.

the first one is a model designed to fire a crap load of bbs at once. the second is my favorite cuz u can stuff anything in the barrel and it WILL fly out at about 500 fps (depending on diameter).

the yellow r the ball bearings which i feel r the heart of the whole assembly. kinda like a bolt in a door. when they r released into a clevis the the fun begins.

the orange is the plug. it blocks the gas. this must be sealed perfectly at all time. a good o-ring usually does it.

the green is the mechanism that keep the ball bearings locked. when it is pressed it releases the plug by freeing the ball bearings from a small wedge on the inner body. the wedge bares the load of the gas pressure against the plug.

the dark blue is the spring that keeps everything in check and make it easy to reset which is done by pushing the button release all the way in to set the plug then letting the button go to set the ball bearings.

the second design works kinda like a coaxial. a disk (blue) and the plug come together to make what i call a piston. the whole valve assembly work as a "mechanical pilot".

<a href="http://s90.photobucket.com/albums/k273/ ... img003.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... img003.jpg" border="0" alt="Photobucket"></a>

<a href="http://s90.photobucket.com/albums/k273/ ... img002.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... img002.jpg" border="0" alt="Photobucket"></a>

sorry if the pics r too big.

the valve can be easily recreated with a dremal, a dowel, ball bearings, and a few tubes that fit loosely but very close into each other.

WHY PAY FOR IT WHEN U CAN MAKE IT?

- ghostman01

- Specialist 3

- Posts: 372

- Joined: Fri Nov 23, 2007 9:15 am

or by means of machining or brass fittings.....the valve can be easily recreated with a dremal, a dowel, ball bearings, and a few tubes that fit loosely but very close into each other.

exactly. i used a different method though. i made a functioning flat version of this valve with a dremal and a 2cm thick piece of aluminum i ripped off a mofset out of an old tv. my dremal got stolen so i can't do too much right now.

WHY PAY FOR IT WHEN U CAN MAKE IT?

- potatoflinger

- Sergeant 2

- Posts: 1136

- Joined: Thu Nov 02, 2006 3:26 pm

- Location: Maryland

There is a much simpler way to do this, just make a backwards coaxial, where what would normally be the barrel is the air chamber and what would normally be the chamber is the barrel. Then you could have a small pilot valve (a schrader would probably work) to pilot the piston. This way, you only need one seal, and it wouldn't even have to be with O-rings, it could be neoprene or rubber.

It's hard to soar with eagles when you're working with turkeys.

true. i just wanted to put another option on the table. this way there is no gas wasted on on piloting.

it is posible to use a rubber or neoprene seal on both designs. it sure would made them easier to prduce.

the other point of this design is for the shells to be loaded into a launcher. i'm working on a revolving launcher. but it can be used for anything though. it's ur choice.

i see what ur sayin though. this is how i'd go about it.

<a href="http://s90.photobucket.com/albums/k273/ ... xshell.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... xshell.jpg" border="0" alt="Photobucket"></a>

it is posible to use a rubber or neoprene seal on both designs. it sure would made them easier to prduce.

the other point of this design is for the shells to be loaded into a launcher. i'm working on a revolving launcher. but it can be used for anything though. it's ur choice.

i see what ur sayin though. this is how i'd go about it.

<a href="http://s90.photobucket.com/albums/k273/ ... xshell.jpg" target="_blank"><img src="http://i90.photobucket.com/albums/k273/ ... xshell.jpg" border="0" alt="Photobucket"></a>

WHY PAY FOR IT WHEN U CAN MAKE IT?

- Lentamentalisk

- Sergeant 3

- Posts: 1202

- Joined: Tue Aug 07, 2007 5:27 pm

- Location: Berkeley C.A.

but there is gas wasted on the piloting... the entire pilot volume is always wasted, no matter what, unless you redirect it to fire more ammo, and the the effectivity goes way down.

One little critique on your design. Either remove the spring entirely, or make it the absolute weakest you can find anywhere, because the weaker it is, the faster it will vent.

One little critique on your design. Either remove the spring entirely, or make it the absolute weakest you can find anywhere, because the weaker it is, the faster it will vent.

Do not look back, and grieve over the past, for it is gone;

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

thanks. the spring must be only strong enough to help reset the piston.

but for the 2 designs up top the pilot is done mechanically so there is little to no gas waste. i guess that "pilot" isn't the word for it because piloting is a gas operation. i'll call it a release.

also, on the coax design i drew,i wanna know what everyone's thoughts are on using a plug instead of a shreader.

but for the 2 designs up top the pilot is done mechanically so there is little to no gas waste. i guess that "pilot" isn't the word for it because piloting is a gas operation. i'll call it a release.

also, on the coax design i drew,i wanna know what everyone's thoughts are on using a plug instead of a shreader.

WHY PAY FOR IT WHEN U CAN MAKE IT?

ur prolly right about the spring. i think as long as i keep it well lubed i wont need it. i'll look into that further.

i don't want to use a schrader because i'm gonna be loading this into a revolving launcher as soon as i finish it. i want a firing pin to hit the plug and fire it like a primer. if i was just gonna shoot it from my hands id use a schrader. the schrader has to leak for a second then it fires. i want instant fire. and i'm not gonna use an air pump as a power source. i'm gonna use propane through the fill valve. like airsoft. cuz that's wat i'm gonna use it for. it's gonna be more powerfull and have more distance than store bought. and it's tons cheaper. u can use it for whatever u want.

i don't want to use a schrader because i'm gonna be loading this into a revolving launcher as soon as i finish it. i want a firing pin to hit the plug and fire it like a primer. if i was just gonna shoot it from my hands id use a schrader. the schrader has to leak for a second then it fires. i want instant fire. and i'm not gonna use an air pump as a power source. i'm gonna use propane through the fill valve. like airsoft. cuz that's wat i'm gonna use it for. it's gonna be more powerfull and have more distance than store bought. and it's tons cheaper. u can use it for whatever u want.

WHY PAY FOR IT WHEN U CAN MAKE IT?

I really don't see what materials you could machine this out of. I doubt unless you are godly, that you can get an accurate metal shell/barrel to hold high pressures.

If you are planning on making it out of PVC, I see it being WAY too bulky with a lot of wasted space.

If you can make this, then that would be totally awesome. If you're looking for cheapness and less work, just do a basic burst disk cartridge.

If you are planning on making it out of PVC, I see it being WAY too bulky with a lot of wasted space.

If you can make this, then that would be totally awesome. If you're looking for cheapness and less work, just do a basic burst disk cartridge.

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

not to mention the power of my burst disk cartridge design is a lot better than the madbull king grenades...

but should be a fun little project none-the-less.

but should be a fun little project none-the-less.

- Lentamentalisk

- Sergeant 3

- Posts: 1202

- Joined: Tue Aug 07, 2007 5:27 pm

- Location: Berkeley C.A.

It could be quite easily made out of copper, though the fill valve would need to be reworked. A schrader may still be your best choice, when it comes to size, or a presta with a schrader adapter that you just screw on when you are filling, to make it safer. I just may have to do this... Will post a pic in a sec of the design, it seems simple enough.

The barrel is something like 3/4", the chamber is like 1.25-1.5", thats a standard reducer, with the ridge dremmeled out, and a bike valve of some sort in the back for filling. The back is just a normal end cap soldered on, with a big hole drilled in the back for the exhaust valve thingy.

The barrel is something like 3/4", the chamber is like 1.25-1.5", thats a standard reducer, with the ridge dremmeled out, and a bike valve of some sort in the back for filling. The back is just a normal end cap soldered on, with a big hole drilled in the back for the exhaust valve thingy.

Do not look back, and grieve over the past, for it is gone;

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

yes i plan on using pvc for the outer shell. i'll shape the dome with heat. i might not even do it. a cylinder will hold more gas than a sphere anyways.

for the piston and pilot plug i got some leftover fiberglass resin.

the fill valve i can get from lighters.

but if ur talkin about the 2 designs up top i already made a functioning flat version of the release mechanism. all i'd have to do is wedge it into the back half of the gas plug. don't even need a spring. when i get a camera i'll be able to post it.

another thing that i still find funny and that most of u wont believe is that i can make a lot of parts out of paper and watered down school glue. it drys rock hard and lasts like forever.

the only thing that suck about paper is that it takes about 24 hours to fully dry.

for the piston and pilot plug i got some leftover fiberglass resin.

the fill valve i can get from lighters.

but if ur talkin about the 2 designs up top i already made a functioning flat version of the release mechanism. all i'd have to do is wedge it into the back half of the gas plug. don't even need a spring. when i get a camera i'll be able to post it.

another thing that i still find funny and that most of u wont believe is that i can make a lot of parts out of paper and watered down school glue. it drys rock hard and lasts like forever.

the only thing that suck about paper is that it takes about 24 hours to fully dry.

WHY PAY FOR IT WHEN U CAN MAKE IT?

- Lentamentalisk

- Sergeant 3

- Posts: 1202

- Joined: Tue Aug 07, 2007 5:27 pm

- Location: Berkeley C.A.

We generally just don't like our cannons to be water soluable... especially because compressing and decompressing air (which I know you said you wouldn't be using,) causes a lot of water to condense. Also, elmers glue just really isn't that strong...i-will wrote:another thing that i still find funny and that most of u wont believe is that i can make a lot of parts out of paper and watered down school glue. it drys rock hard and lasts like forever.

the only thing that suck about paper is that it takes about 24 hours to fully dry.

But as long as what ever you are doing will not be holding any pressure, more power to you! DIY!

Do not look back, and grieve over the past, for it is gone;

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

Do not be troubled about the future, for it has not yet come;

Live life in the present, and make it so beautiful that it will be worth remembering.

what about a coax with an integrated and replaceable burst disk. like a burst disk cartrage that twistlocks into the barrel of a coax. OMG THAT WOULD BE AWESOME. and make it all fit into a 40mm barrel. that's gonna be hard. BUT SO AWESOME.

and i spray my paper parts with clear coat water proofing paint and let it soak in (which requires more dry time). the paper has to be layered no less than 2cm thick. it's the same method they use for plywood and that stuff is crazy strong.

when ur poor u find cheap ways to do things.

try it. u'll be suprise. DIY FOR LIFE!

and i spray my paper parts with clear coat water proofing paint and let it soak in (which requires more dry time). the paper has to be layered no less than 2cm thick. it's the same method they use for plywood and that stuff is crazy strong.

when ur poor u find cheap ways to do things.

try it. u'll be suprise. DIY FOR LIFE!

Last edited by i-will on Thu Oct 02, 2008 1:22 am, edited 2 times in total.

WHY PAY FOR IT WHEN U CAN MAKE IT?