Have some springs from sprinklers that fit well in 2" sch. 80, that being rated @ 400 PSI I'm thinking 2-3x mix.

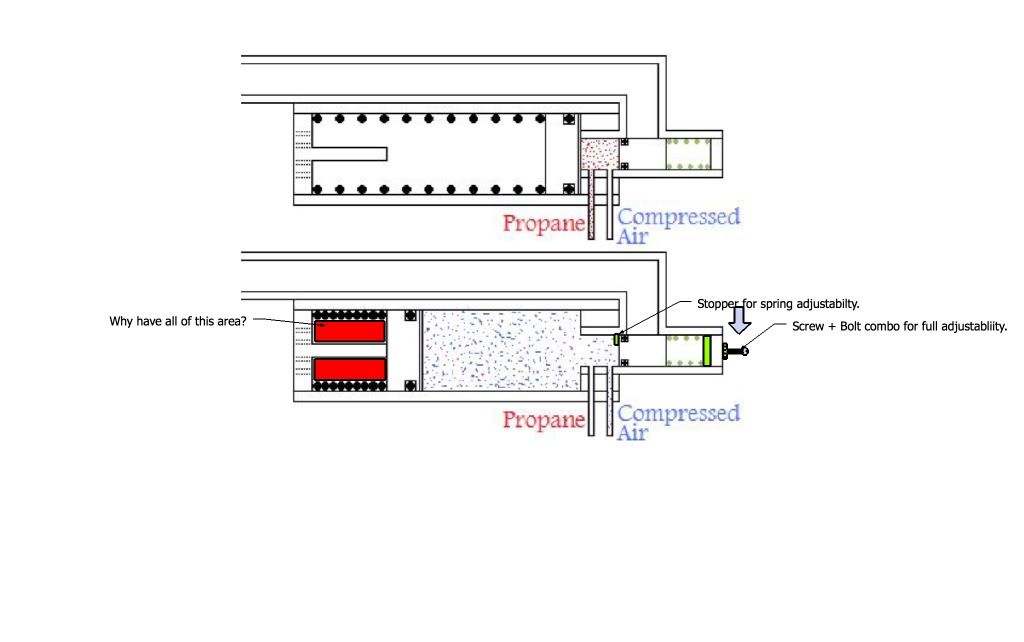

Spring-piston exhausted hybrid chamber

I'm thinking to make hybrid chamber, as in revolving chambers(?), that would use a spring loaded piston within the chamber to exhaust. Firstly the chamber would be pressurized with fuel and compressed air, so much so that the piston would fully redact into a seated state. So the piston doesn't slam against the housing only after combustion = possible breakage. After the projectile leaves the barrel the spring, attached to the piston, will uncompress exhausting the chamber.

Have some springs from sprinklers that fit well in 2" sch. 80, that being rated @ 400 PSI I'm thinking 2-3x mix.

Have some springs from sprinklers that fit well in 2" sch. 80, that being rated @ 400 PSI I'm thinking 2-3x mix.

Forgot to draw one element. Attached to the piston (valve) a sear will catch it in the right most position (open). When the chamber piston reaches its right most position it will release the sear, closing the valve.

- Attachments

-

- springhybrid.jpg (24.4 KiB) Viewed 4203 times

Yeah, this would certainly work.

Oddly though, it's never really caught on as an idea, despite being proposed over four years ago on Spudtech.

Oddly though, it's never really caught on as an idea, despite being proposed over four years ago on Spudtech.

Does that thing kinda look like a big cat to you?

- jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

2 quick thoughts...

1) A lighter weight spring would allow greater range in mixtures and the pressure exiting the chamber would draw the piston to the right pushing burnt gasses out.

2) Every time the chambers rotate the fuel and pressurizing feed lines will have to reconnect, then every time you fire the connections will be under burst of stress causing deformities in the mating connections. That will cause problems with fuel and pressure amounts etc...

1) A lighter weight spring would allow greater range in mixtures and the pressure exiting the chamber would draw the piston to the right pushing burnt gasses out.

2) Every time the chambers rotate the fuel and pressurizing feed lines will have to reconnect, then every time you fire the connections will be under burst of stress causing deformities in the mating connections. That will cause problems with fuel and pressure amounts etc...

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 6 times

It needs to be adjustable based on mix, so i added a screw and bolt combo like JSR uses for adjustable detents. Also with a weaker spring, you won't have much space behind the piston

I love lamp

- jackssmirkingrevenge

- Five Star General

- Posts: 26189

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 551 times

- Been thanked: 328 times

Why have a spring behind the piston at all, since it has an o-ring?

hectmarr wrote:You have to make many weapons, because this field is long and short life

At a lower ROF, if your piston reseals, you end up drawing a pretty strong vacuum in the chamber. I propsed that idea somewhere for a full/semi auto combustion, but as the chamber(s) heat up, the effect becomes less pronounced, and takes much longer. Depending on the mix, you could simply fill with fuel/air and deal with the combustion residue as a buffer gas. A 10x air oxidized hybrid produces more pressure than an oxy-fuel mix mix, simply because you start with so much more pressure. Once I get a milling attachment for my lathe and/or an actual vice for my drill press, I will attempt a high ROF hybrid for paintball.

You do need to make sure you have a recess for the spring, otherwise the pressure acting on the piston will pancake it. The piston must also be able to stand the pressure on it, considering that it is only partially supported.

Depending on your bore, you should consider an airspring behind the piston in the valve. If you have 1" SA, 800PSI would require an 800lb spring to hold the valve shut. You would also have to worry about the spring pancaking when the extra SA is exposed. We discussed all this here.

You do need to make sure you have a recess for the spring, otherwise the pressure acting on the piston will pancake it. The piston must also be able to stand the pressure on it, considering that it is only partially supported.

Depending on your bore, you should consider an airspring behind the piston in the valve. If you have 1" SA, 800PSI would require an 800lb spring to hold the valve shut. You would also have to worry about the spring pancaking when the extra SA is exposed. We discussed all this here.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

Ragnarok-

The propane metering placement is the only thing that seems unique. Great link, probably peak through the sub-forum on second thought.

Jrrdw-

1)My MS Paint are consistently out of scale. The metal springs in mind are 1/8" wire or so, and from sprinkler bodies. What I had planned was piece of 1 1/2" PVC to slide in behind and to the left of the chamber spring. Then I'd epoxy a metal nut to said PVC and put a segment of all thread, with a bearing around one end, that end fixed to the outer chamber wall, that allowing me to adjust the spring pressure. Figure I'd fiddle with the all-thread adjustment until I could get the chamber piston to seat with minimal pressure.

2)Bagging the multiple chambers for now, but I'd use a rotary O-ring seal having the fuel/air pipes along the center line of the chambers. Not coaxially in each chamber, but in the mount for the multiple chambers.

Lockednloaded-

The red area is space for the spring, a stop for chamber piston, and a disc with a threaded center.

I do plan on having the stopper and full adjustability devices. Good catch. Didn't draw all the features, for instance the propane/air metering and the loading mechanism.

Jackssmirkingrevenge-

The lights are blinking, I'm thinking. Design change..

Ramses-

Bent my mind over the vacuum issue, I figure I'll treat the fueling scenario as if it were a static chamber, so long as the chamber spring can fully depress allowing the chamber piston to rest on its stop and/or that the pre-combustion gases are of enough pressure.

"but as the chamber(s) heat up, the effect becomes less pronounced, and takes much longer. "

Unsure about this, are you perhaps referring to c3 tippmann design?

Reading the piston design thread, I'll post on it later.

The propane metering placement is the only thing that seems unique. Great link, probably peak through the sub-forum on second thought.

Jrrdw-

1)My MS Paint are consistently out of scale. The metal springs in mind are 1/8" wire or so, and from sprinkler bodies. What I had planned was piece of 1 1/2" PVC to slide in behind and to the left of the chamber spring. Then I'd epoxy a metal nut to said PVC and put a segment of all thread, with a bearing around one end, that end fixed to the outer chamber wall, that allowing me to adjust the spring pressure. Figure I'd fiddle with the all-thread adjustment until I could get the chamber piston to seat with minimal pressure.

2)Bagging the multiple chambers for now, but I'd use a rotary O-ring seal having the fuel/air pipes along the center line of the chambers. Not coaxially in each chamber, but in the mount for the multiple chambers.

Lockednloaded-

The red area is space for the spring, a stop for chamber piston, and a disc with a threaded center.

I do plan on having the stopper and full adjustability devices. Good catch. Didn't draw all the features, for instance the propane/air metering and the loading mechanism.

Jackssmirkingrevenge-

The lights are blinking, I'm thinking. Design change..

Ramses-

Bent my mind over the vacuum issue, I figure I'll treat the fueling scenario as if it were a static chamber, so long as the chamber spring can fully depress allowing the chamber piston to rest on its stop and/or that the pre-combustion gases are of enough pressure.

"but as the chamber(s) heat up, the effect becomes less pronounced, and takes much longer. "

Unsure about this, are you perhaps referring to c3 tippmann design?

Reading the piston design thread, I'll post on it later.

If that little piston's spring is strong enough to keep it shut during pressurizing, wouldn't it close before the chamber has lost all its pressure? You'll then have to manually vent the chamber to release the spring tension for each next shot.

<a href="http://www.launchpotatoes.com"><img src="http://www.launchpotatoes.com/images/up ... 2.PNG"></a>

http://www.LaunchPotatoes.com

http://www.LaunchPotatoes.com

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

I've mostly been lurking. The intertia of the piston may solve that for you. If the piston had the same density as the gas, then yes, but as a denser object, it may take enough time to lose inertia, reverse and return. This inertial delay may be enough to vent the chamber. Basicaly, the chamber can vent and drop pressure faster than the spring and piston can close. It might work.sgort87 wrote:If that little piston's spring is strong enough to keep it shut during pressurizing, wouldn't it close before the chamber has lost all its pressure? You'll then have to manually vent the chamber to release the spring tension for each next shot.

With the heat up issue, I meant that if the chamber is at a higher temperature (say 150*F) it will take slightly longer for the chamber to cool the gasses left. They will also cool to a higher temperature, reducing the total vacuum pulled.

With the spring-piston mechanism, you can assume that, when it is time to fuel the gun, there is zero gas in the chamber. The "dead volume" caused by the fuel injection and spark system is probably negligible.

With the spring-piston mechanism, you can assume that, when it is time to fuel the gun, there is zero gas in the chamber. The "dead volume" caused by the fuel injection and spark system is probably negligible.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

"Forgot to draw one element. Attached to the piston (valve) a sear will catch it in the right most position (open). When the chamber piston reaches its right most position it will release the sear, closing the valve. " -Me

^Gort. Idk if you have seen, but on BTB's pneumatic repeater he uses a quick connect fitting to lock and release. Unsure if he did it, but I've removed the internal piston/spring/ o-ring that is used as a valve/ejector/seal to the male piece. Since the quick connect fittings won't be a used for the passage of any gasses I only need the ball bearing locking portion.

Honestly wasn't thinking of doing it that way Tech, but why not? Thankfully that area I left longer with the expectation to later cut shorter.

Ramses, two issues I have with the vacuum system. As you mentioned the heat creating a dynamic of the vacuum, and is the net force of the vacuum being enough to practically work with. Logically I like a vacuum from the passive mechanic standpoint.

Also I've decided to externally meter the propane, for the sake of ROF. I can inject the air and propane at the same time, rather then separately (timely).

^Gort. Idk if you have seen, but on BTB's pneumatic repeater he uses a quick connect fitting to lock and release. Unsure if he did it, but I've removed the internal piston/spring/ o-ring that is used as a valve/ejector/seal to the male piece. Since the quick connect fittings won't be a used for the passage of any gasses I only need the ball bearing locking portion.

Honestly wasn't thinking of doing it that way Tech, but why not? Thankfully that area I left longer with the expectation to later cut shorter.

Ramses, two issues I have with the vacuum system. As you mentioned the heat creating a dynamic of the vacuum, and is the net force of the vacuum being enough to practically work with. Logically I like a vacuum from the passive mechanic standpoint.

Also I've decided to externally meter the propane, for the sake of ROF. I can inject the air and propane at the same time, rather then separately (timely).

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

The last hang up is preventing back-flow. Seems as if I will need some tertiary component between the chamber and source to prevent an otherwise straight shot. Could this be as simple as? : "Orifice - A restricted passage in a hydraulic circuit. Usually a small drilled hole to limit flow or to create a pressure differential in a circuit."

Then arising what type of valve will shut off before chamber and source equalize? If you pulse the source in timed intervals how could you employ clockwork-like mechanics, rather then electronically laced? Electronics: Toxic swap gas (allegorically speaking, maybe subtly )

)

Then arising what type of valve will shut off before chamber and source equalize? If you pulse the source in timed intervals how could you employ clockwork-like mechanics, rather then electronically laced? Electronics: Toxic swap gas (allegorically speaking, maybe subtly

- Attachments

-

- 2x 3-way valves - If I could get the electronic timing circuits I'm thinking this:

- ElectronicHybridFuelingExhaustingCircut.jpg (10.16 KiB) Viewed 3976 times