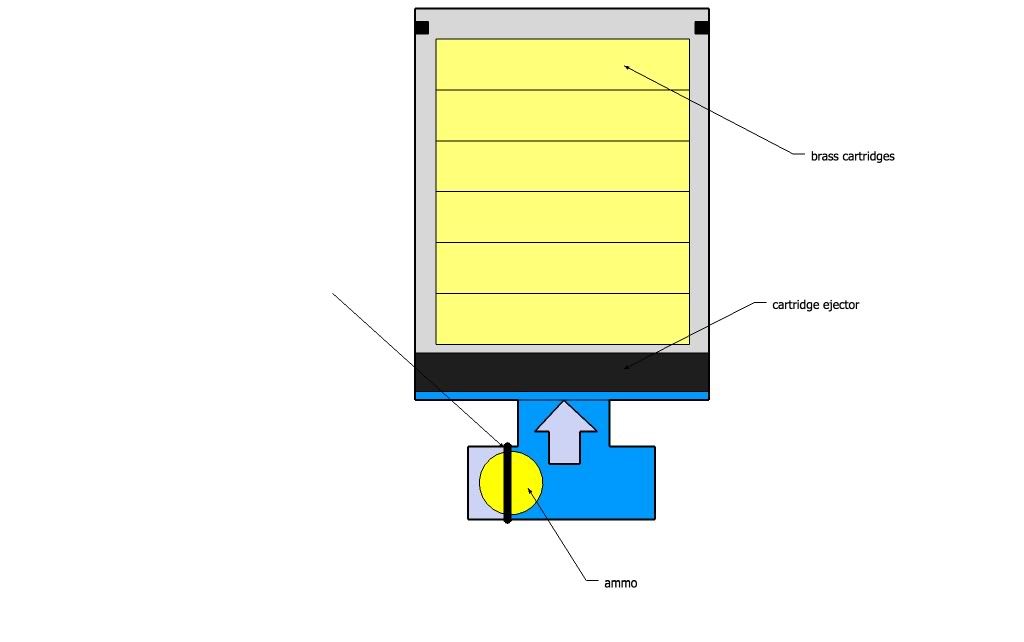

"valveless" cartridge concept

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Why is there a hole in the top of the cart.?

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

That's fairly simple. Because the cartridge doesn't have a top. When loaded in a magazine, it could be oriented any way, so Jack will have a number of "air ports" set so that there's always one which will at least partially line up with the air input.Gun Freak wrote:Why is there a hole in the top of the cart.?

Does that thing kinda look like a big cat to you?

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Oh ok I didn't think of that... thanks.

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

Nice breakthrough with the seals, but you still need to hold the projectile in the cartridge somehow.

I would consider adding mass to the bolt, rather than increasing spring pressure. That might ease the closing, while reducing the cyclic rate of fire.

I would consider adding mass to the bolt, rather than increasing spring pressure. That might ease the closing, while reducing the cyclic rate of fire.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Precisely what Rag replied, there will probably be 4 ports in each cartridge.Gun Freak wrote:Why is there a hole in the top of the cart.?

I'm using 0.22" airgun pellets in a 5.5mm barrel, they fit very tightly so no chance of them falling out.you still need to hold the projectile in the cartridge somehow.

Good point, the more inertia the bolt has the further back it will travel and it will give the next cartridge more time to feed. As to rate of fire, this can be regulated by altering trigger flow too.I would consider adding mass to the bolt, rather than increasing spring pressure. That might ease the closing, while reducing the cyclic rate of fire.

In retrospect, I think adding a seal at the breech and around the cartridge would have probably given my coaxial prototypesa much better chance of cycling, especially since there was so little chamber volume so some sort of delay before the projectile leaves the barrel is essential. Hmm...

Well, back to the subject of this thread, the prototype is happening

- muzzle energy with 0.22" pellets with restricted cartridge movement, representing the maximum power attainable by a final design

- cartridge blowback force and the likelyhood of enough energy to cycle a semi/full auto action

Since there has been some recent interest in epoxy casting, I've added diagrams of the internals while casting (Fig.1) and the final components (Fig.2). Some items of note:

-the cartridge has not yet been ported in order to enable the cartridge body to be used as a inner mould for the breech.

-the mouth of the cartridge uses the same tube as the barrel, crimped at the end to prevent the projectile from being blown into the cartridge

- the 1/8" fitting that will provide the air feed port has been temporarily plugged with foam, which will then be drilled out after the epoxy has cured.

- the barrel, breech seal and cartridge are held with a 5mm mandrel, not 5.5mm, in order to have the seal cure in an unstressed state, meaning it will be less able to expand as the projectile passes through it and will maintain a stronger grip and better seal.

Edit:

seems I overdid it with the projectile seal, it won't pop at 800 psi - though the cartridge certainly will, enough to take the chamber seal with it

Back to the drawing board...

- Attachments

-

- Internal diagrams

- VLCINTERNAL.JPG (36.94 KiB) Viewed 3457 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

sort of. I was unclear in my use of cyclic rate of fire. It is a firearms term, meant to measure the maximum ROF the bolt, feeding, etc. would be able to achieve. I ignored filling time in my statement.As to rate of fire, this can be regulated by altering trigger flow too.

You can pretty much increase ROF by increasing the flow up until the cyclic rate of fire. Even if the cartridge filled instantly, the next shot can't happen until that cartridge is ejected and the next one chambered. Increasing the mass slows this, while increasing spring force speeds it. It's a mass spring system

Although as far as I can see, that site assumes constant spring force, rather than a linear force spring rate.

POLAND_SPUD wrote:even if there was no link I'd know it's a bot because of female name

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

It has to work first though... needs a re-think before I rebuild though.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

It is pretty ridiculous, I think the valveless gun needs to be totally perfected before you put flying brass into the mix...POLAND_SPUD wrote:no offence this is probably the most ridiculous design you posted...

I am getting the impression that you want to build it becasue you want to see flying brass

I did make a quick design that you are sure to love

you still get your flying brass...

I love lamp

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Lockednloaded wrote:I did make a quick design that you are sure to love

you still get your flying brass...

It had been suggested back in the spudtech days that maybe I ought to have someone stand next to me while I shoot and drop spent cartridges after every shot

I think the valveless gun needs to be totally perfected before you put flying brass into the mix...

What is there to perfect exactly?

Edit: making a new prototype, similar concept but with less tight breech seal, and cartridge made from the same material as the barrel.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Completed the cycle animation, at least that's how I hope it will work

- Attachments

-

- vlcmodanicycle.gif (32.87 KiB) Viewed 3333 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Lockednloaded

- Staff Sergeant

- Posts: 1566

- Joined: Thu Sep 03, 2009 9:38 pm

- Location: Texas, USA

- Been thanked: 7 times

This is much better than the air injector needle thingy. The principle of KISS always prevails in then end. How do you expect the cartridges to eject out of the side?

I love lamp

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

The idea is that the cartridge strikes the off-centre ejector which tips it out of the side, pretty much identical to what I had done with combustion cartridges:Lockednloaded wrote:How do you expect the cartridges to eject out of the side?

[youtube][/youtube]

Last edited by jackssmirkingrevenge on Sun Nov 19, 2017 7:21 am, edited 1 time in total.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jakethebeast

- Corporal 5

- Posts: 945

- Joined: Sat Jul 03, 2010 4:20 pm

- Location: Jakes cave

looks good, waiting for moar results!

I'm afraid that I'm not going to add anything to the conversation here...

I just had to say that about three or four times now, I've seen this thread in the 'recent topics' list, where the title has been conveniently shortened to 'valveless car'. I keep clicking it thinking that someone's developed a new kind of engine

Yes, it is rather sad that this has gotten me multiple times. Today.

I just had to say that about three or four times now, I've seen this thread in the 'recent topics' list, where the title has been conveniently shortened to 'valveless car'. I keep clicking it thinking that someone's developed a new kind of engine

Yes, it is rather sad that this has gotten me multiple times. Today.

I wonder how much deeper the ocean would be without sponges.

Right now I'm having amnesia and deja vu at the same time. I think I've forgotten this before.

Add me on msn!!! insomniac-55@hotmail.com

Right now I'm having amnesia and deja vu at the same time. I think I've forgotten this before.

Add me on msn!!! insomniac-55@hotmail.com

What? Never seen a Wankel engine?Insomniac wrote:I keep clicking it thinking that someone's developed a new kind of engine

Does that thing kinda look like a big cat to you?