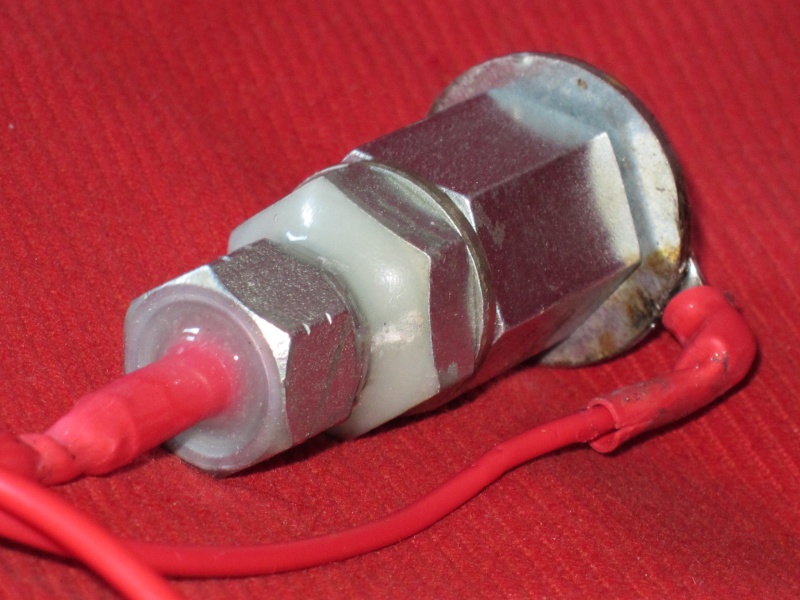

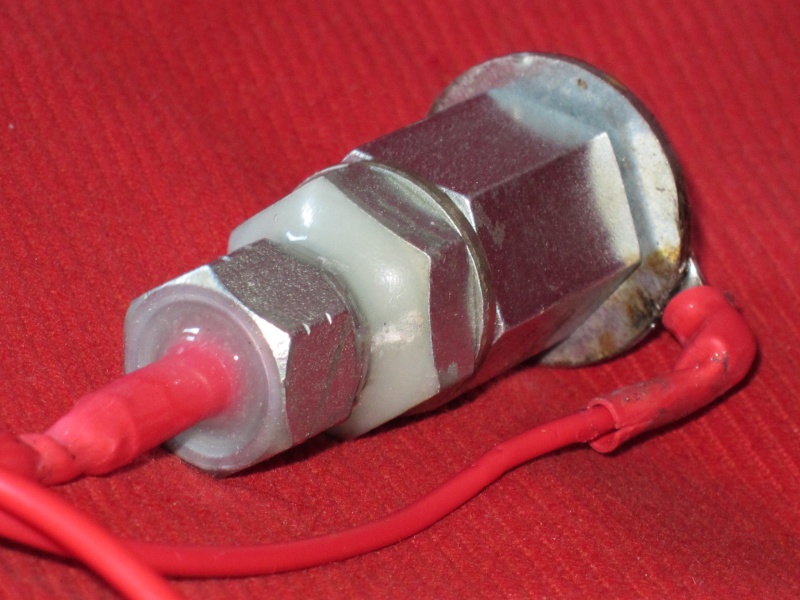

I have not done the system of electrodes / / but I opted instead for a plug HM.

You can also see a seal that helps me when I want to unscrew the spark plug to clean it.

I tested this config up to 40bar and no worries, the spark is good.

hectmarr wrote:You have to make many weapons, because this field is long and short life

Yes, and also there's a lot less friction drag - that's why modern tanks have smoothbore barrelsPetitlu wrote:But in a smooth barrel not rotating the bullet ...

Note with a sphere or an arrow that's not important ...

What's the thickness of the copper?will support the smooth barrel Mix40?

What does this mean exactly - did you put it inside an iron tube?covered with iron

hectmarr wrote:You have to make many weapons, because this field is long and short life

hectmarr wrote:You have to make many weapons, because this field is long and short life

hectmarr wrote:You have to make many weapons, because this field is long and short life

No worries, will post them tomorrowPetitlu wrote:Thank you!

I can not wait to test all these shoes!

Don't bother too much, they are going to be fired after allI will remove the burrs, no problem!

hectmarr wrote:You have to make many weapons, because this field is long and short life