Something like this then

Hybrid ThorJack

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

I would say 6-8mm

As DYI pointed out though it would be helpful if you had some kind of grinding wheel available in order to round off the nose.

As DYI pointed out though it would be helpful if you had some kind of grinding wheel available in order to round off the nose.

hectmarr wrote:You have to make many weapons, because this field is long and short life

yes I have a portable grinder, but I need to find a wheel to sharpen the tungsten ...

Sharpening will not change the hardness of tungsten?

EDIT :the length is good?

http://www.ebay.co.uk/itm/6MM-X-50MM-RO ... _500wt_969

Sharpening will not change the hardness of tungsten?

EDIT :the length is good?

http://www.ebay.co.uk/itm/6MM-X-50MM-RO ... _500wt_969

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

I doubt the friction from grinding will generate enough heat to affect the hardness.Sharpening will not change the hardness of tungsten?

I would try at least one round with no grinding at all, to see if it acts like a "punch".

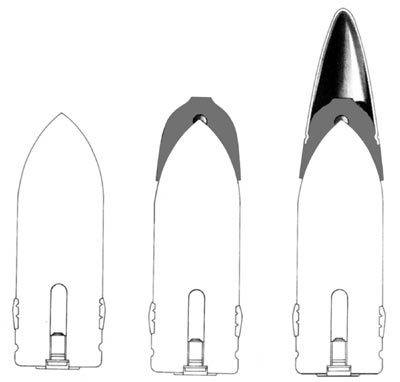

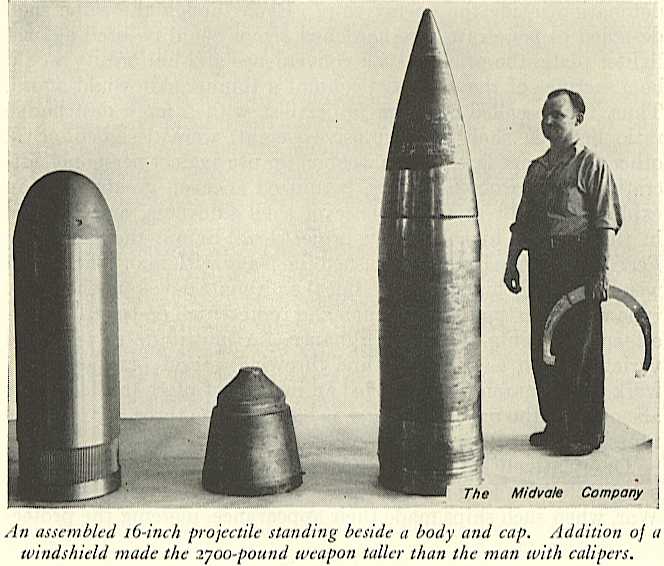

Remember the point doesn't have to be very sharp. Look at a typical armour piercing shell from a battleship gun:

While the assembled shell has a very pointed shape in order to travel smoothly through the air, the actual penetrating body (to the left in both pictures) has a relatively blunt profile.

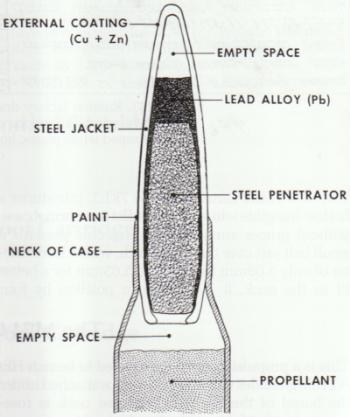

The same is true of many steel cores for armour piercing bullets, some of which even have a blunt profile:

That looks perfect!

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

The problem with the rifled barrel is the twist rate. A longer projectile needs to be spun faster in order to be stabilised, and the BP barrel you have is made to stabilise relatively short spherical or conical bullets so the twist rate is probably quite low.Petitlu wrote:you'll make shoes for rifled barrel?

or fins for smooth barrel?

If you can find a way to cut the rods to short lengths (for example 10mm long) it should work in the rifled barrel, but then I don't think you will have enough mass for reliable penetration.

I think the best solution is to use the rods without modification, as they are, except perhaps rounding off the tip slightly. I will make fins and pusher plates for the 12mm smoothbore barrel.

By the way, have you tried shooting the 8mm bearing sabot yet?

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

Excellent  I will make some fins over the coming days.

I will make some fins over the coming days.

One thing though, I would contact the ebay seller first:

One thing though, I would contact the ebay seller first:

Maybe they can grind a 45º point on the rods for you for a reasonable price?PROVIDE TAILOR MADE ROD SIZE AND LENGTH MIN ORDER 10 PCS. 15-20 DAYS LEAD TIME

ABLE TO MAKE LATHE TOOL CUTS MATERIAL HARDNESS : HRC40

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

FOR SCIENCE!!!Petitlu wrote:But it's for science!

It's €3.80 per round, not bad when you compare it to the cost of "real" ammunition.

hectmarr wrote:You have to make many weapons, because this field is long and short life

Firstly, I suppose I should clarify that when I talk about carbide drills, I mean drill bits made of SOLID CARBIDE. Not carbide tipped.

Tungsten is a better penetrator at high speeds, where material strength isn't as important. Whether it will be superior to tungsten carbide at the relatively low speeds a hybrid like this is capable of remains to be seen. Tungsten metal is certainly easier to work than carbide - a normal grinding wheel should do just fine.

As far as I know, most W alloys of the type you'd buy off ebay are not heat treated in the first place, so grinding the round to a point, even with no regard for cooling, shouldn't make much difference. Typical tungsten alloys are, compared to steel, quite hard without any heat treatment. If cooling is paid attention to, you'll not make a difference in strength regardless.

Also: just because blunt rounds have been used doesn't make them equally effective penetrators. If you're trying to kill things on the other side of the armour, spalling is working in your favour. It also means that you're applying more force to the round at a higher rate, which is not helping penetration in most cases.

Bottom line: try the tungsten rods. It should be fun

Tungsten is a better penetrator at high speeds, where material strength isn't as important. Whether it will be superior to tungsten carbide at the relatively low speeds a hybrid like this is capable of remains to be seen. Tungsten metal is certainly easier to work than carbide - a normal grinding wheel should do just fine.

As far as I know, most W alloys of the type you'd buy off ebay are not heat treated in the first place, so grinding the round to a point, even with no regard for cooling, shouldn't make much difference. Typical tungsten alloys are, compared to steel, quite hard without any heat treatment. If cooling is paid attention to, you'll not make a difference in strength regardless.

Also: just because blunt rounds have been used doesn't make them equally effective penetrators. If you're trying to kill things on the other side of the armour, spalling is working in your favour. It also means that you're applying more force to the round at a higher rate, which is not helping penetration in most cases.

Bottom line: try the tungsten rods. It should be fun

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

- jackssmirkingrevenge

- Five Star General

- Posts: 26204

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 572 times

- Been thanked: 345 times

Very true, and also there are manufacturing considerations especially for small arms ammunition made in large quantities, a truncated cone is easier to make than an ogive tip, so it's not necessarily the most effective shape in terms of effect.DYI wrote:just because blunt rounds have been used doesn't make them equally effective penetrators. If you're trying to kill things on the other side of the armour, spalling is working in your favour. It also means that you're applying more force to the round at a higher rate, which is not helping penetration in most cases.

I'll be happy to make fins and sabots for those tooBottom line: try the tungsten rods. It should be fun

hectmarr wrote:You have to make many weapons, because this field is long and short life