My project - HPA powered SMG for .50 lead balls

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

Hello. First post here, so let me give a brief background. I am into guns, and having shot various machine guns in the Army, I sure would enjoy being able to shoot one for fun. I live in a state which doesn't have any way to get a license for Class 3 machine guns, so the only legal option is to go with an air powered non-firearm. I've had several paintball markers, worked with CO2 regulators and lawn sprinkler valves in a few simple air cannons, and have some understanding of how all the valves involved work. By day, I am an engineer and my talents center on being able to design 3D models of precise mechanical components.

I had been looking at the Caselman air powered SMG blueprints for a while, and in the last few weeks have modeled it all into 3D. I have many disagreements with the way that gun works, and finally have decided I would rather spend my time designing one from the ground up, than to spend hundreds for our machine shop to make parts for the Caselman design, and end up with mediocre performance at best.

To this end, my plan is to build a full automatic air rifle utilizing a rifled .50 caliber barrel from a muzzle loader, and to run HPA through the internals, not regulated down to 800 PSI or less like most paintball markers, but to actually be using full bottle pressure inside to give the rounds as much power as possible. Using various attempts at calculating it, I believe if I were to use the 290 grain PowerBelt rounds and an internal pressure of 3000 PSI, then with a 24 inch barrel I should be able to achieve round performance similar to that of a .45ACP pistol round.

My use of Google has been bringing me to this forum frequently enough, I figured I'd just register and might as well start talking with you guys here about my project. Most of my concerns will be how I can put valves together that will seal, hold, and survive the wear of usage. I don't know how much an O-ring can be trusted to seal at 3000 PSI, for example, or whether that's laughably impossible and any seals must be press-fit, and any valves must be poppet-style (not spool). I have been trying to focus the design on what I would consider to fire from a "locked" breech - that is, rather than like a paintball marker where barrel pressure drives the round forward, and drives the bolt back to recock, instead I would want to barrel pressure to only drive the round forward, and for the bolt to actually be held in a sealed position by the barrel pressure, only releasing to recock after pressure has dropped (and spring force takes over). I will try to get some pictures put together of the CAD models I've been working with on this, to better illustrate my concepts for how the action would work.

Anyways, gotta run for now, but I hope to return and provide more details, pictures, and so forth. If anyone is looking seriously at the Caselman air powered SMG, I would be more than happy to share my CAD model of it with you (I can export it as STP files).

I had been looking at the Caselman air powered SMG blueprints for a while, and in the last few weeks have modeled it all into 3D. I have many disagreements with the way that gun works, and finally have decided I would rather spend my time designing one from the ground up, than to spend hundreds for our machine shop to make parts for the Caselman design, and end up with mediocre performance at best.

To this end, my plan is to build a full automatic air rifle utilizing a rifled .50 caliber barrel from a muzzle loader, and to run HPA through the internals, not regulated down to 800 PSI or less like most paintball markers, but to actually be using full bottle pressure inside to give the rounds as much power as possible. Using various attempts at calculating it, I believe if I were to use the 290 grain PowerBelt rounds and an internal pressure of 3000 PSI, then with a 24 inch barrel I should be able to achieve round performance similar to that of a .45ACP pistol round.

My use of Google has been bringing me to this forum frequently enough, I figured I'd just register and might as well start talking with you guys here about my project. Most of my concerns will be how I can put valves together that will seal, hold, and survive the wear of usage. I don't know how much an O-ring can be trusted to seal at 3000 PSI, for example, or whether that's laughably impossible and any seals must be press-fit, and any valves must be poppet-style (not spool). I have been trying to focus the design on what I would consider to fire from a "locked" breech - that is, rather than like a paintball marker where barrel pressure drives the round forward, and drives the bolt back to recock, instead I would want to barrel pressure to only drive the round forward, and for the bolt to actually be held in a sealed position by the barrel pressure, only releasing to recock after pressure has dropped (and spring force takes over). I will try to get some pictures put together of the CAD models I've been working with on this, to better illustrate my concepts for how the action would work.

Anyways, gotta run for now, but I hope to return and provide more details, pictures, and so forth. If anyone is looking seriously at the Caselman air powered SMG, I would be more than happy to share my CAD model of it with you (I can export it as STP files).

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

With that sort of CV, glad to have you on the forumSchlauncha wrote:Hello. First post here, so let me give a brief background.

The Caselman is quite an elegant design for what it is, what exactly are your objections to the design?I have many disagreements with the way that gun works, and finally have decided I would rather spend my time designing one from the ground up, than to spend hundreds for our machine shop to make parts for the Caselman design, and end up with mediocre performance at best.

If you want to estimate power, GGDT is your friend: http://thehalls-in-bfe.com/GGDT/index.htmlUsing various attempts at calculating it, I believe if I were to use the 290 grain PowerBelt rounds and an internal pressure of 3000 PSI, then with a 24 inch barrel I should be able to achieve round performance similar to that of a .45ACP pistol round.

With a good enough valve and long enough barrel, you should be able to achieve the sort of power levels you want even with 1000 psi or less. I don't have GGDT available at this PC but will try and make some models at home.

Certainly most PCP air rifles work in the 2000-3000 psi bracket and believe me, they've got plenty of o-rings in them! These work most of the time, but of course no matter how good they are they need to be replaced eventually.Most of my concerns will be how I can put valves together that will seal, hold, and survive the wear of usage. I don't know how much an O-ring can be trusted to seal at 3000 PSI, for example, or whether that's laughably impossible and any seals must be press-fit, and any valves must be poppet-style (not spool).

I have been trying to focus the design on what I would consider to fire from a "locked" breech - that is, rather than like a paintball marker where barrel pressure drives the round forward, and drives the bolt back to recock, instead I would want to barrel pressure to only drive the round forward, and for the bolt to actually be held in a sealed position by the barrel pressure, only releasing to recock after pressure has dropped (and spring force takes over).

Any particular reason for this?

Looks like the mechanisms you should be looking at are the FX autos.

Here's the patent for the FX Revolution:

http://www.google.com/patents/US2006027 ... on&f=false

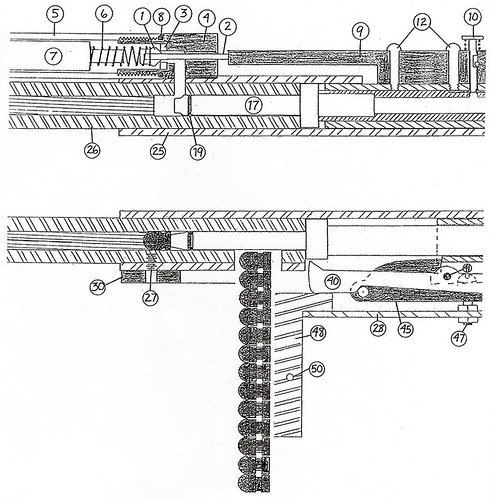

There's also the Monsoon, this is mine taken apart

It works similar to an assault rifle which I'm sure you're familiar with, where air is bled from the barrel to drive a piston.

The difference is that it uses air escaping from the barrel *after* the projectile has left the muzzle. The Monsoon in particular basically has a suppressor where the rear wall is actually a piston, which recocks the hammer and reloads the magazine.

Here's a design based on a similar concept I had dreamt up a while ago, haven't actually made it though:

I think you should lay out some specifications, for example:I will try to get some pictures put together of the CAD models I've been working with on this, to better illustrate my concepts for how the action would work.

- expected projectile velocity

- expected level of accuracy

- minimum and maximum operating pressure

- overall dimensions and weight

- budget

- tool and material availability

- magazine capacity

This will ensure you will get the specific sort of advice you're after as you already seem to have a lot of basics covered.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

Thank you very much for showing me that GGDT program. I will monkey around with it and see what sort of results I get.

Here are my specifications (goals):

Projectile to carry power equal to 9mm or higher, and travel subsonic

-Heavy rounds could go slower, light rounds would be faster, etc

-Appropriately size volume of air for each shot, balancing efficiency/quietness against getting enough performance

Accuracy to be +/- 6" at 50 feet single shot, and a maximum 3 foot diameter pattern during sustained full auto firing

-Setting the bar low here. Accuracy by fire rate is the name of the game

-Main usage will be tearing up paper targets, cans, pinatas, old electronics, etc for fun

Pressure to be based on that necessary to achieve performance. Operating from CO2 would be great if possible.

-Looking at wimpy (.32ACP) performance of Caselman at unregulated CO2 pressure, I'm estimating HPA 2000-3000 PSI is needed

Barrel length is 24", I'm trying to get the receiver to stay as short as possible to retain rifle form factor.

-Shorter receiver would also be less material, less depth of boring, so quicker/easier/cheaper to build

-Weight should be under 15 lbs. My current designs (minus tank) sit at 8 lbs.

Budget, if performance output can be confidently expected to be satisfactory, could run up to $1000

-Rifled 24" barrel, C02 tanks already owned. Would need to buy an HPA tank, fittings, and all raw materials.

Working at a tool & die shop, we'll be able to get tool steels, case harden and grind stuff, and make about any part in high precision

-But I'd be paying for the materials and labor like any of our customers, maybe a little discount I hope.

-Pro-E is my biggest "tool" advantage, I think. Measure twice, cut once, same thing applies.

Magazine capacity should be able to accept either a tube of balls (as many as I can get a spring to drive) or a single-stack mag of 20 PowerBelts

-Maybe even just scale the Tippmann Cyclone Feed to .50 cal, give it a strong enough spring to move lead balls, and use hopper feed

-Lead balls will not seal as well, but they are MUCH cheaper than the powerbelts.

-I'm slowly leaning further and further from powerbelts and towards simply only doing ball ammo instead.

Other thoughts:

If it can operate at CO2 levels, that may be good for testing, but I'll probably still end up with (regulated) HPA to avoid frostbite and pressure fade due to the high flow this will see. Although I don't know if HPA freezes up just like CO2 does - I'm guessing not nearly as much, since HPA doesn't change states like CO2 does (in the bottle as mostly liquid) and I would guess that's where it's drawing in so much thermal energy (getting cold).

My thoughts regarding the action's cycle, in terms of open bolt, closed bolt, direct blowback, etc, are that in order to get the most power into the round, the bolt cannot open itself to the magazine feeding area until pressure has dropped (after the round has left the barrel). My current design (well, favorite of dozens) is stemmed from the action of a Tiberius paintball marker. The bolt has a pin aiming rearward which enters into what works like an unbalanced spool valve. When cocked, this pin seals with an O-ring, created a closed chamber for the shot charge to build up in. The pin also reaches in and hits a poppet valve inside that shot chamber, so that when the bolt and all are traveling forward, and after the shot, there is no continual air flow from the chamber. But that's a few steps ahead. So the pressure builds up in the shot chamber, pushing forward on this pin. The bolt is held open by the trigger sear. When the trigger is pulled, pressure drives the bolt forward by its piston action on that pin (of only a 1/4" diameter, so it's not huge amounts of force). Upon far enough travel forward, this pin uncorks from that seal, and the shot charge blasts forward through the transfer ports in the bolt. This way, the "shot" doesn't happen until the bolt is far enough forward for the blast not to come back into the magazine (although Tiberius doesn't completely seal that - I would). After the shot and pressure / bolt momentum ceases, spring force drives the bolt back, resealing the shot chamber (which it can easily insert into, because of aforementioned poppet valve keeping the chamber from re-pressurizing yet) and the trigger sear latches, and now the pin is pressing the poppet to refill the shot chamber, and the cycle repeats.

I'm out of lunch break to type about this. Tonight I'll start trying to get snapshots of stuff so it's far more clear than my attempts at describing it.

Here are my specifications (goals):

Projectile to carry power equal to 9mm or higher, and travel subsonic

-Heavy rounds could go slower, light rounds would be faster, etc

-Appropriately size volume of air for each shot, balancing efficiency/quietness against getting enough performance

Accuracy to be +/- 6" at 50 feet single shot, and a maximum 3 foot diameter pattern during sustained full auto firing

-Setting the bar low here. Accuracy by fire rate is the name of the game

-Main usage will be tearing up paper targets, cans, pinatas, old electronics, etc for fun

Pressure to be based on that necessary to achieve performance. Operating from CO2 would be great if possible.

-Looking at wimpy (.32ACP) performance of Caselman at unregulated CO2 pressure, I'm estimating HPA 2000-3000 PSI is needed

Barrel length is 24", I'm trying to get the receiver to stay as short as possible to retain rifle form factor.

-Shorter receiver would also be less material, less depth of boring, so quicker/easier/cheaper to build

-Weight should be under 15 lbs. My current designs (minus tank) sit at 8 lbs.

Budget, if performance output can be confidently expected to be satisfactory, could run up to $1000

-Rifled 24" barrel, C02 tanks already owned. Would need to buy an HPA tank, fittings, and all raw materials.

Working at a tool & die shop, we'll be able to get tool steels, case harden and grind stuff, and make about any part in high precision

-But I'd be paying for the materials and labor like any of our customers, maybe a little discount I hope.

-Pro-E is my biggest "tool" advantage, I think. Measure twice, cut once, same thing applies.

Magazine capacity should be able to accept either a tube of balls (as many as I can get a spring to drive) or a single-stack mag of 20 PowerBelts

-Maybe even just scale the Tippmann Cyclone Feed to .50 cal, give it a strong enough spring to move lead balls, and use hopper feed

-Lead balls will not seal as well, but they are MUCH cheaper than the powerbelts.

-I'm slowly leaning further and further from powerbelts and towards simply only doing ball ammo instead.

Other thoughts:

If it can operate at CO2 levels, that may be good for testing, but I'll probably still end up with (regulated) HPA to avoid frostbite and pressure fade due to the high flow this will see. Although I don't know if HPA freezes up just like CO2 does - I'm guessing not nearly as much, since HPA doesn't change states like CO2 does (in the bottle as mostly liquid) and I would guess that's where it's drawing in so much thermal energy (getting cold).

My thoughts regarding the action's cycle, in terms of open bolt, closed bolt, direct blowback, etc, are that in order to get the most power into the round, the bolt cannot open itself to the magazine feeding area until pressure has dropped (after the round has left the barrel). My current design (well, favorite of dozens) is stemmed from the action of a Tiberius paintball marker. The bolt has a pin aiming rearward which enters into what works like an unbalanced spool valve. When cocked, this pin seals with an O-ring, created a closed chamber for the shot charge to build up in. The pin also reaches in and hits a poppet valve inside that shot chamber, so that when the bolt and all are traveling forward, and after the shot, there is no continual air flow from the chamber. But that's a few steps ahead. So the pressure builds up in the shot chamber, pushing forward on this pin. The bolt is held open by the trigger sear. When the trigger is pulled, pressure drives the bolt forward by its piston action on that pin (of only a 1/4" diameter, so it's not huge amounts of force). Upon far enough travel forward, this pin uncorks from that seal, and the shot charge blasts forward through the transfer ports in the bolt. This way, the "shot" doesn't happen until the bolt is far enough forward for the blast not to come back into the magazine (although Tiberius doesn't completely seal that - I would). After the shot and pressure / bolt momentum ceases, spring force drives the bolt back, resealing the shot chamber (which it can easily insert into, because of aforementioned poppet valve keeping the chamber from re-pressurizing yet) and the trigger sear latches, and now the pin is pressing the poppet to refill the shot chamber, and the cycle repeats.

I'm out of lunch break to type about this. Tonight I'll start trying to get snapshots of stuff so it's far more clear than my attempts at describing it.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Attached a performance estimate with 2000 psi and an efficient valve pushing a lead ball through you 0.50" barrel, I think performance is close to what you would be pleased with. Do play with GGDT, it gives you a fairly accurate idea of what parameters are important and how power will vary if you alter pressure, chamber volume etc.Schlauncha wrote:Thank you very much for showing me that GGDT program. I will monkey around with it and see what sort of results I get.

HPA guns are loud. If you want power, it will be loud. Efficient guns tend to be big, so for something hand held you will have to compromise. If adding a silencer is not an option, legally I assume it isn't, then noise is something you will have to live with.Projectile to carry power equal to 9mm or higher, and travel subsonic

-Heavy rounds could go slower, light rounds would be faster, etc

-Appropriately size volume of air for each shot, balancing efficiency/quietness against getting enough performance

Assuming a consistent valve, you should be able to achieve it. One thing to remember is that big airguns are very hungry for air, so if you're running at 2000 psi regged down from 3000, power is going to drop off fairly quickly especially at full auto.Accuracy to be +/- 6" at 50 feet single shot, and a maximum 3 foot diameter pattern during sustained full auto firing

-Setting the bar low here. Accuracy by fire rate is the name of the game

-Main usage will be tearing up paper targets, cans, pinatas, old electronics, etc for fun

This is why you should strive to do "more with less", if you can get the performance you want with 1000 psi, then a 3000 psi tank will last longer.

Some things to know about CO<sub>2</sub>:Pressure to be based on that necessary to achieve performance. Operating from CO2 would be great if possible.

-Looking at wimpy (.32ACP) performance of Caselman at unregulated CO2 pressure, I'm estimating HPA 2000-3000 PSI is needed

- it is very sensitive to temperature, a cold gun will be significantly weaker than a warm one

- it is significantly denser than air, meaning it moves slower down the barrel. This means that all things being equal, filling a chamber with 500 psi of CO<sub>2</sub> gives you less power than 500 psi of air.

Try and keep custom parts to a bare minimum, thanks to eBay and such you will find a lot of off-the-shelf parts at a reasonable price that can fit the bill.Working at a tool & die shop, we'll be able to get tool steels, case harden and grind stuff, and make about any part in high precision

-But I'd be paying for the materials and labor like any of our customers, maybe a little discount I hope.

-Pro-E is my biggest "tool" advantage, I think. Measure twice, cut once, same thing applies.

In the auto game, spherical projectiles are massive benefit when it comes to magazine options. Heck, you could even have a hopperMagazine capacity should be able to accept either a tube of balls (as many as I can get a spring to drive) or a single-stack mag of 20 PowerBelts

-Maybe even just scale the Tippmann Cyclone Feed to .50 cal, give it a strong enough spring to move lead balls, and use hopper feed

-Lead balls will not seal as well, but they are MUCH cheaper than the powerbelts.

-I'm slowly leaning further and further from powerbelts and towards simply only doing ball ammo instead.

See, I didn't need to argue against CO<sub>2</sub> after allOther thoughts:

If it can operate at CO2 levels, that may be good for testing, but I'll probably still end up with (regulated) HPA to avoid frostbite and pressure fade due to the high flow this will see. Although I don't know if HPA freezes up just like CO2 does - I'm guessing not nearly as much, since HPA doesn't change states like CO2 does (in the bottle as mostly liquid) and I would guess that's where it's drawing in so much thermal energy (getting cold).

I don't think your concerns here are justified. In the case of the Caselman for example:My thoughts regarding the action's cycle, in terms of open bolt, closed bolt, direct blowback, etc, are that in order to get the most power into the round, the bolt cannot open itself to the magazine feeding area until pressure has dropped (after the round has left the barrel).

You have the same pressure acting on the projectile and the bolt.

The projectile is a tiny little thing, free to move. The bolt on the other hand is a big heavy thing that is held shut by a spring. This means that the projectile accelerates much, much faster and would have barely moved by the time the projectile leaves the muzzle.

Still if that doens't convince you, take a look at the mechanisms I mentioned in the previous post as they literally have no option to function before the projectile leaves the barrel and the gas can escape to affect the mechanism.

On another note, you might want to take a simpler route - consider using smaller calibre projectiles and making an HPA BBMG.

All it takes is air source -> valve -> chamber with round projectiles -> barrel

Here's what I managed to do with 800 psi and plastic airsoft BBs:

[youtube][/youtube]

http://www.spudfiles.com/forums/hpa-air ... 21457.html

Upping the calibre to say 0.32" and using lead balls or steel ball bearings would give you much, much more power. Accuracy by rate of fire it will be

Remember, what counts is weight of fire. A 0.50" with some sort of blowback mechanism firing 2 rounds per second will be less devastating than a 0.25" firing 10 rounds per second.

Air economy is also something you need to think about. What you have in mind will be a real air hog that will probably only shoot 10-15 rounds from a large HPA paintball tank before it needs to be refilled, you'd better have a SCUBA tank handy.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

sagthegreat

- Specialist 3

- Posts: 343

- Joined: Thu Feb 16, 2012 5:23 pm

- Location: Leesburg

- Contact:

I was waiting for a project like this

Try this mech.

but instead of blowgun use a pressure release valve ment for more then 1000psi

Try this mech.

but instead of blowgun use a pressure release valve ment for more then 1000psi

- Attachments

-

- vlnc_115.gif (14.24 KiB) Viewed 7413 times

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

I need to revisit my choice regarding caliber here... For how much power (volume x pressure) it will take to fire each .50 caliber round at the desired velocity, an HPA tank would run out before the magazine! Okay, we want something that's powerful enough to be on-par with firearms, but for the same rate of power flow, you could have a slow thump thump thump of devastatingly powerful rounds, or you could have a fast buzz of much smaller rounds, of lesser individual power. All said and done, I'm starting to think it might make sense to scale down to around .22 or .25 caliber. I really like .22 since a person could get those barrels dirt cheap all day long. For what it's worth, .22 pellets (and bb's?) are then also commercially available. Ahh... now it clicks why the only two air machine guns I've seen commercially available are both in .22 caliber. So long as a person can get the pressure and flow high enough to achieve a powerful enough round (possibly requiring a heavier round), then it could be fitting what I want.

Here are the links for the two I had looked at:

http://fullyautomaticairgun.com/

http://air-ordnance.com/

Sorry for alot of thinking out loud here. I will try to get more pictures uploaded later, but I have a feeling if I scale down to .22 then I'll be going for off-the-shelf valves, and a great big redesign that will bear little resemblance to this current one.

Here are the links for the two I had looked at:

http://fullyautomaticairgun.com/

http://air-ordnance.com/

Sorry for alot of thinking out loud here. I will try to get more pictures uploaded later, but I have a feeling if I scale down to .22 then I'll be going for off-the-shelf valves, and a great big redesign that will bear little resemblance to this current one.

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

You've never seen a Drozd?

[youtube][/youtube]

Many mods available...check the bbmachinegun forums...circuit boards, hpa conversions, 6mm conversions, high cap drum mags....the list is long.

[youtube][/youtube]

Many mods available...check the bbmachinegun forums...circuit boards, hpa conversions, 6mm conversions, high cap drum mags....the list is long.

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

I've had a Umarex Steel Storm (that I switched from 6-shot burst to full auto by removing the burst cam) and I figure the Drozd is about the same, maybe a little better. But still a "bb gun" in my opinion, something that wouldn't be able to stop a raccoon or zombie.

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

Fair nuff. Can't talk about Rocky and his buddys on this forum.

Shoebox sized zombies are the order of the day then?

Shoebox sized zombies are the order of the day then?

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Even 0.177" BBs can be devastating if thrown fast enough.

At the speed of sound, a steel BB will have around 14 ft/lbs of energy. If you go for lead BBs of the same calibre at the same speed it goes up to 22 ft/lbs. That might not sound like much compared to firearms, but firing at a high rate it will chew through pretty much anything.

Using HPA, supersonic BBs are more than possible even with "only" 1000 psi.

At the speed of sound, a steel BB will have around 14 ft/lbs of energy. If you go for lead BBs of the same calibre at the same speed it goes up to 22 ft/lbs. That might not sound like much compared to firearms, but firing at a high rate it will chew through pretty much anything.

Using HPA, supersonic BBs are more than possible even with "only" 1000 psi.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

The more I look at that $600 .22 SMG from http://air-ordnance.com/ the more I start to wonder if it might just make the most sense to SAVE money and buy something that works. $600 is alot, but they're getting 600fps with .22 pellets, and that's feeding from a 100 round belt. I love me some belt fed shootage, let me tell ya. Plus, the thing is made by a guy with a last name of Tippmann, so I have confidence these guys know what they're doing. Compared to the other link from above, for cheaper, this one is offering much better bang for the buck.

I sent them a message asking whether their rating of 600FPS on CO2 could be improved upon with HPA regulated to higher pressures than the CO2 provided. I'd expect they will have tested this and could let me know. If it brings it up to much better velocities, then I think I'll just buy that and call it good.

I sent them a message asking whether their rating of 600FPS on CO2 could be improved upon with HPA regulated to higher pressures than the CO2 provided. I'd expect they will have tested this and could let me know. If it brings it up to much better velocities, then I think I'll just buy that and call it good.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

That sounds like a sensible plan. If you have another $100 to spend I'm sure velocity could be boosted. Remember that with hammer valves, higher pressure doesn't necessarily mean higher power. Hammer springs can be strengthened, valves can be streamlined for better flow and have their springs weakened, barrels can be lengthened etc.

You also have take into account that more air flowing through the system will put more strain on the reloading mechanism.

Here's the patent drawings: http://www.google.com/patents/US2011018 ... as&f=false

You also have take into account that more air flowing through the system will put more strain on the reloading mechanism.

Here's the patent drawings: http://www.google.com/patents/US2011018 ... as&f=false

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

I emailed with them and they said that HPA was a possibility, and that their .22 SMG can run up to around 1200-1300 PSI on regulated HPA, achieving higher velocities. I sent in an order Friday evening, so we'll see how it goes. Out at my folks' house they have a problem with squirrels raiding their bird feeders but more importantly tearing holes in the siding trying to nest inside the walls of their house, so where we had relied on a scoped .17HMR rifle before, now with something like this ("Not" a gun, quieter and less lethal) now even my mother can operate this to take out squirrels from the kitchen window. Not to be sexist - the kitchen window just has the best field of fire!

Ordering direct from their site, it was $600, plus another $50 for the optional stock (for form factor) and then I ordered a few tins of pellets. Now I notice the same thing sells for $550 off Amazon.com, which is a bit of a bummer to find it's $50 more directly from their website, when usually it should be cheaper to buy direct. Oh well. I think they've earned their money - this gun just looks awesome and the quality and functionality (BELTFED!) just lives up to the Tippmann name.

Ordering direct from their site, it was $600, plus another $50 for the optional stock (for form factor) and then I ordered a few tins of pellets. Now I notice the same thing sells for $550 off Amazon.com, which is a bit of a bummer to find it's $50 more directly from their website, when usually it should be cheaper to buy direct. Oh well. I think they've earned their money - this gun just looks awesome and the quality and functionality (BELTFED!) just lives up to the Tippmann name.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Be sure to post your results when you get it

Not in my experience, for example all the Sherline stuff I've bought would have been more expensive direct from the factory. A dealer has the time and energy to work out good deals, while the manufacturer is usually more concerned with... well, manufacturingNow I notice the same thing sells for $550 off Amazon.com, which is a bit of a bummer to find it's $50 more directly from their website, when usually it should be cheaper to buy direct.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Schlauncha

- Private

- Posts: 12

- Joined: Fri Oct 12, 2012 5:15 am

I'll be picking it up from the UPS depot after work, and heading out to the range this evening. I'll probably take a few catalogs or phone books out there to count page penetration on, for a quick and easy way to compare its power to other things (like .22LR or a .177 Gamo Silent Cat). I plan on picking up a whole bunch of Knox gelatin to make some bricks of ballistic gel again, I had good success last time I made those. I use the 10% gelatin to water by weight, following general internet instructions, and I cast them into aluminum foil "loaf pans" which makes a nice size block, about 3"x5"x18" as I approximately remember it. Hopefully I'll get to that within a few days. I'll take some videos of it later and upload them to Youtube.