3/4" NPT (m) to 1" G (f)

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

As the title says, I need to connect something with male 3/4" NPT threads to something that has female 1" G threads. A direct adapter does not exist (afaik), so what other options exist that would minimize dead space?

Tapping a 1" G plug maybe?

Or will a male 1" G to female 1" NPT adapter plus a reducer bushing not actually create significant dead space?

G thread = BSPP thread

Thanks...

It's a massive Euro-style QEV with 1" G threads all around, plus a massive 3/4" NPT slide valve.... I'm making a piece-together big bore pneumatic (minimal machining is a requirement).

Tapping a 1" G plug maybe?

Or will a male 1" G to female 1" NPT adapter plus a reducer bushing not actually create significant dead space?

G thread = BSPP thread

Thanks...

It's a massive Euro-style QEV with 1" G threads all around, plus a massive 3/4" NPT slide valve.... I'm making a piece-together big bore pneumatic (minimal machining is a requirement).

Last edited by PVC Arsenal 17 on Wed Oct 31, 2012 9:06 pm, edited 4 times in total.

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

bump re-purposed thread

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

That's probably what I would go for.Tapping a 1" G plug maybe?

hectmarr wrote:You have to make many weapons, because this field is long and short life

Here is the minmal machining method that is probably cheaper unless you already have a 3/4 NPT tap and correct drill size.

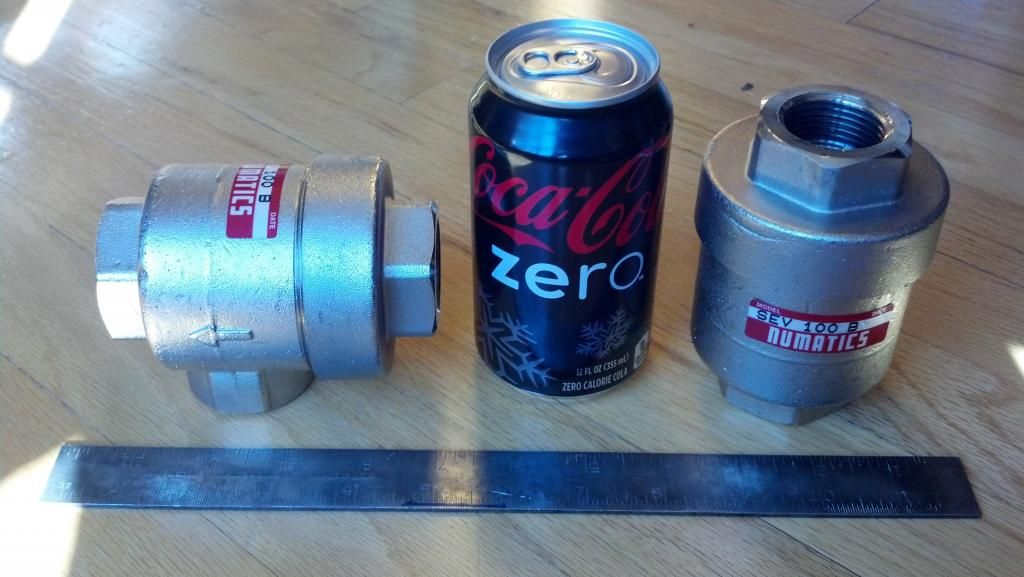

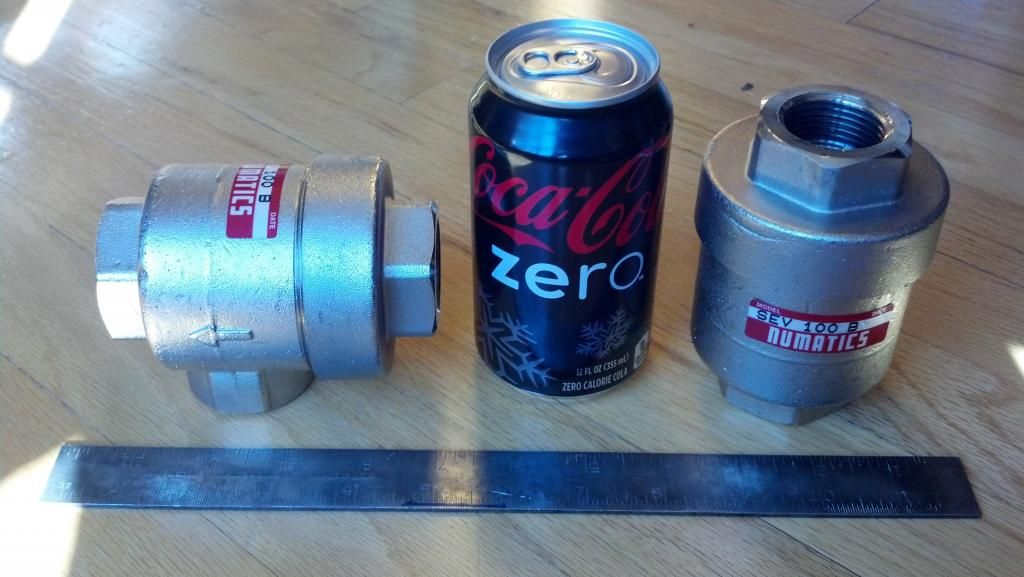

As jsr mentioned the tapped plug is better as can be seen in this picture.

As jsr mentioned the tapped plug is better as can be seen in this picture.

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

Thanks for the pictures, Dewey! I do have a 3/4" NPT tap but I'll need to find a 59/64" drill bit.

I'm concerned about making a centered hole using my whacky drill press. Would you advise drilling from the hollow end, or drilling from the closed end using progressively larger bits?

I'm concerned about making a centered hole using my whacky drill press. Would you advise drilling from the hollow end, or drilling from the closed end using progressively larger bits?

You could also use a 15/16" drill.PVC Arsenal 17 wrote:Thanks for the pictures, Dewey! I do have a 3/4" NPT tap but I'll need to find a 59/64" drill bit.

I'm concerned about making a centered hole using my whacky drill press. Would you advise drilling from the hollow end, or drilling from the closed end using progressively larger bits?

Get a a cheap Harbor Freight machinist (drill press) vise. Well worth it!

Center punch accurately on the flat of the hex side.

Start with 3/16" as a pilot and progressively enlarge. Use oil to keep drill bit cool and aid drilling.

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

Much appreciated, Dewey. While I'm at it I'll pick up a cheapo belt sander for my knife sharpening needs.

Home Depot has a 4" vise that is cheap.

It appears Harbor Freight has quit stocking the drill press vises.

It appears Harbor Freight has quit stocking the drill press vises.

-

PVC Arsenal 17

- Staff Sergeant 3

- Posts: 1762

- Joined: Mon Mar 27, 2006 4:18 pm

- Location: United States

Well here they are:

Undoubtedly BSPP threads, not NPT. But, NPT male threads into them no problem. In fact since it's a straight thread, the additional insertable depth almost makes it seem more secure than the typical NPT-NPT connection which offers less engagement.

It doesn't seem like blow-out would be likely. If anything goes wrong it would probably be leakage. I'm tempted to go ahead without adapters and just use a ton of pipe dope and teflon tape.

If anyone thinks I'm a candidate for a Darwin award, I'll happily sell them for $35 shipped to the lower 48.

Undoubtedly BSPP threads, not NPT. But, NPT male threads into them no problem. In fact since it's a straight thread, the additional insertable depth almost makes it seem more secure than the typical NPT-NPT connection which offers less engagement.

It doesn't seem like blow-out would be likely. If anything goes wrong it would probably be leakage. I'm tempted to go ahead without adapters and just use a ton of pipe dope and teflon tape.

If anyone thinks I'm a candidate for a Darwin award, I'll happily sell them for $35 shipped to the lower 48.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

hehe please sell them to Petitlu, I'm sure he'll put them to some insane but ultimately entertaining use

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

haha I almost forgot about it myselfPetitlu wrote:In the fact Jack, I did not forget the test Neverlost!

hectmarr wrote:You have to make many weapons, because this field is long and short life

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Sorry to hear that, hope it was not related to unexpected loud noises from the garden! Great to see you back and looking forward to some cool stufPetitlu wrote:I had family problems for a moment but now I can make the test!

I digress, apologies to PVC for the hijack.

hectmarr wrote:You have to make many weapons, because this field is long and short life