Nice!

I looks a little bent though, shouldn't you have put a spacer between the cannon and chamber before tightening that zip tie?

Bait Cannon, Help Needed

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

baitcannon

- Private

- Posts: 15

- Joined: Tue Jul 18, 2017 7:37 pm

Somehow when I put it all together it came out that way. Not exactly sure why. So I split a peice of rubber fuel line between the barrel and chamber and zip tied it together.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

As long as your solvent welding is sound you should be fine

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

baitcannon

- Private

- Posts: 15

- Joined: Tue Jul 18, 2017 7:37 pm

jackssmirkingrevenge wrote:As long as your solvent welding is sound you should be fine

It is for sure, have done multiple test fires. With a small spud, I'm exceeding 100 yards easily, but I'm still kicking myself for my foul up in the valve build.

I've done lots of PVC plumbing for drains and such, I can't for the life of me figure out why it didn't come out square. It was definitively odd.

-

baitcannon

- Private

- Posts: 15

- Joined: Tue Jul 18, 2017 7:37 pm

So here is the build.

If requested, I can move all these images to a thread detailing the build.

For now this will do.

http://imgur.com/a/oNtKk

If requested, I can move all these images to a thread detailing the build.

For now this will do.

http://imgur.com/a/oNtKk

-

baitcannon

- Private

- Posts: 15

- Joined: Tue Jul 18, 2017 7:37 pm

Ok, the two bad things about this build......

1.) I have had random trouble with my disk and seal. First thing is that at around 85 psi or less, there isn't enough pressure to unseat the piston. That or I don't have a tight enough seal around the disk/piston and the irrigation housing to create enough pressure to unseat it.

Now, Hubb had a three disk stack and the neoprene washer. I was trying to eliminate the bulk of the piston and allow for a larger opening. With my design, there is no space to put the rubber o-ring to create an air tight seal.

Also, with a minimal stack, the disk/piston has occasionally gone cock-eye in the valve body where an air compressor can't create enough force to get it back into place. If I had done it like Hubb did, then I probably wouldn't have that problem.

2.) I cut the collar/bump stop off of the top of the cap of the valve body. My reasoning was to allow myself the space to apply epoxy around the protruding 1/4" npt nipple. I wanted optimal strength.

What is happening now is that I could of used the protrusion/collar as a bump stop and put a bit of rubber gasket on top of the piston/disk. This would have plugged the pilot hole after pressure release allowing optimal air flow to the barrel, without loss through the pilot. I might possibly buy another valve to use the cap if I cannot solve this problem.

Overall, I am happy with the performance so far. I might play around with the disks and go ahead and build it to Hubbs specifications. Even with what I gained using a smaller, lighter piston, I've probably lost it by not being able to use it at lower psi's, and loss through the pilot.

1.) I have had random trouble with my disk and seal. First thing is that at around 85 psi or less, there isn't enough pressure to unseat the piston. That or I don't have a tight enough seal around the disk/piston and the irrigation housing to create enough pressure to unseat it.

Now, Hubb had a three disk stack and the neoprene washer. I was trying to eliminate the bulk of the piston and allow for a larger opening. With my design, there is no space to put the rubber o-ring to create an air tight seal.

Also, with a minimal stack, the disk/piston has occasionally gone cock-eye in the valve body where an air compressor can't create enough force to get it back into place. If I had done it like Hubb did, then I probably wouldn't have that problem.

2.) I cut the collar/bump stop off of the top of the cap of the valve body. My reasoning was to allow myself the space to apply epoxy around the protruding 1/4" npt nipple. I wanted optimal strength.

What is happening now is that I could of used the protrusion/collar as a bump stop and put a bit of rubber gasket on top of the piston/disk. This would have plugged the pilot hole after pressure release allowing optimal air flow to the barrel, without loss through the pilot. I might possibly buy another valve to use the cap if I cannot solve this problem.

Overall, I am happy with the performance so far. I might play around with the disks and go ahead and build it to Hubbs specifications. Even with what I gained using a smaller, lighter piston, I've probably lost it by not being able to use it at lower psi's, and loss through the pilot.

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Generally unless you have an o-ring seal on your piston, you don't need equalization holes - enough air can flow around the piston. By adding the holes, you're making your piston less efficient.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

baitcannon

- Private

- Posts: 15

- Joined: Tue Jul 18, 2017 7:37 pm

I tried doing a disk/piston without the equalization hole. When using the air compressor, you could hear a thump as the pressure built in the pilot and then (what I think) is the gasket releasing the air into the chamber. Even though my gasket isn't perfectly cut, I think that when it starts to compresses as pressure builds, it is squeezing itself larger and sealing to the outside of the irrigation valve. The rubber is fairly soft in comparison to a neoprene washer, and I'm only speculating.jackssmirkingrevenge wrote:Generally unless you have an o-ring seal on your piston, you don't need equalization holes - enough air can flow around the piston. By adding the holes, you're making your piston less efficient.

So, I went ahead and put an equalization hole in it. Reason being is that I am going to use a 250psi mini bike pump to pressurize it while I am out fishing. I want the pumping action to be as smooth as possible. The sealing rubber for the barrel covers the equalization hole, so in theory, it should be acting like a check valve not allowing any air back through.

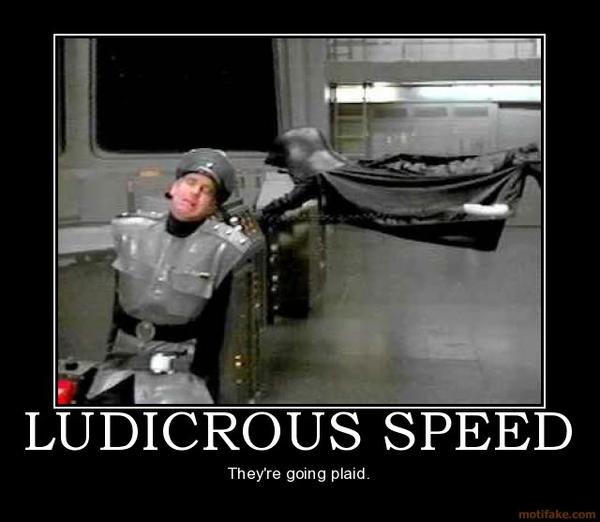

Oh, and I'm not going to pump it to 250psi, that would only give me ludacris speed and bad things happen at ludacris speed.

I did make an o ring out of the stock rubber I have and put it on top of the disk. Then sanded smooth where it will hit the valve cap. I fired off 4 shots, and it is working extremely well! I feel that I'm getting complete flow to the barrel and not much, if any escape into the pilot region. The piston seems to be working with each shot with no issues and seating back no problem.

One final thing I did do is make the end of the barrel tapered to cut the potato cleanly. To me, this is imperative with any build. What I found out is not only is it easier to load, but the potato doesn't seem to have nearly as much pressure against the barrel as it did before, allowing it to exit out the barrel more efficiently.

Two shots, I fired in a direction where I could figure the approximate landing zone to measure by google earth. One shot was 150 yards with a slightly larger spud, and another came out to 220 with a smaller spud. Also checked the pressure of each shot and my air gauge read 120 psi.

I call that success...... 8)

- jackssmirkingrevenge

- Five Star General

- Posts: 26203

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 569 times

- Been thanked: 345 times

Ah. Sounds plausible.Even though my gasket isn't perfectly cut, I think that when it starts to compresses as pressure builds, it is squeezing itself larger and sealing to the outside of the irrigation valve. The rubber is fairly soft in comparison to a neoprene washer, and I'm only speculating.

Oh, and I'm not going to pump it to 250psi, that would only give me ludacris speed and bad things happen at ludacris speed.

The air will be all up in the spud's face and be like move, b¡tch!

edit: can't believe this forum still has a swear filter...

Sounds like itI call that success...

hectmarr wrote:You have to make many weapons, because this field is long and short life